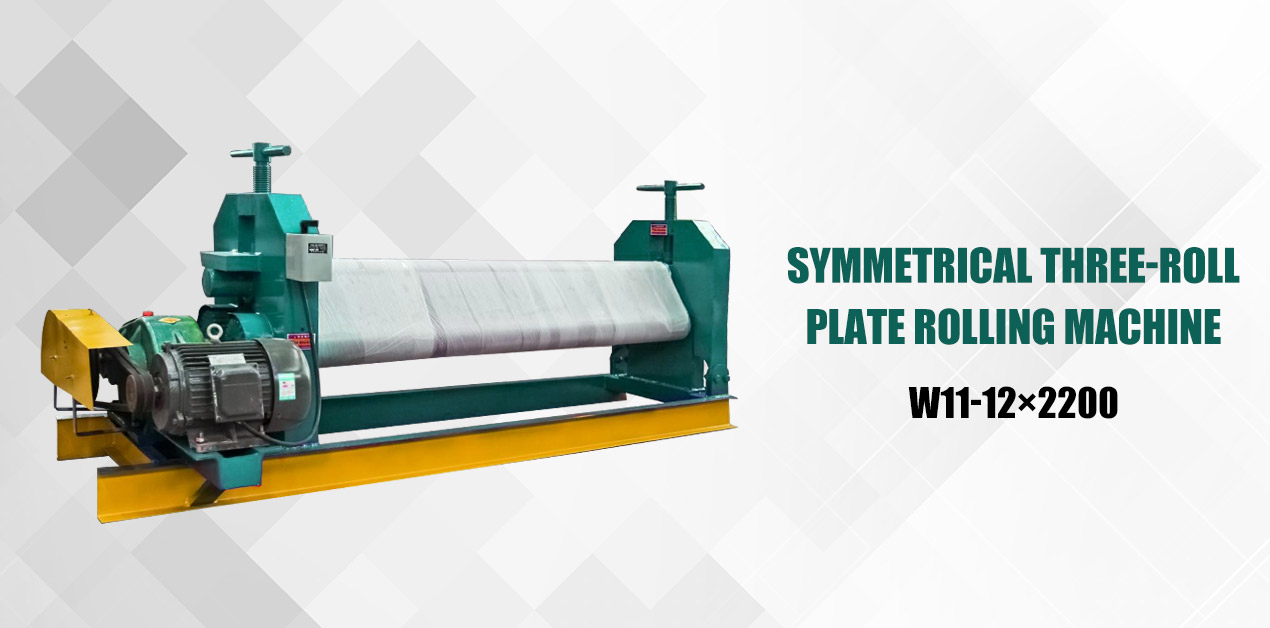

3 roll bending machine parameters

| Model number | W11-12×2200 |

| Work roll | Hollow work roll(high temperature quenching treatment) |

| Maximum coil thickness | 12mm |

| Maximum width | 2200mm |

| Roller working length | 2230mm |

| Plate Yield Limit | δs≤245Mpa |

| Upper roll diameter | Φ245mm |

| Bottom roll diameter | Φ219mm |

| Main motor power | 7.5kw |

| Reducer | JZQ-350 |

| Dimensions | 2.8×1.0×1.0(m) |

Hollow work roll

The up and down roll movement of the work roll completes the coiling action.

Screw

The screw height adjustment mechanism is a mechanism that can adjust the height through a screw.

The mechanism is composed of a screw and a nut. By rotating the screw, the nut is driven to move up and down, so as to realize the height adjustment of the working surface such as the workbench.

Electrical components

Electrical components are famous Siemens brands, which is popular in market.

Stable work ability.

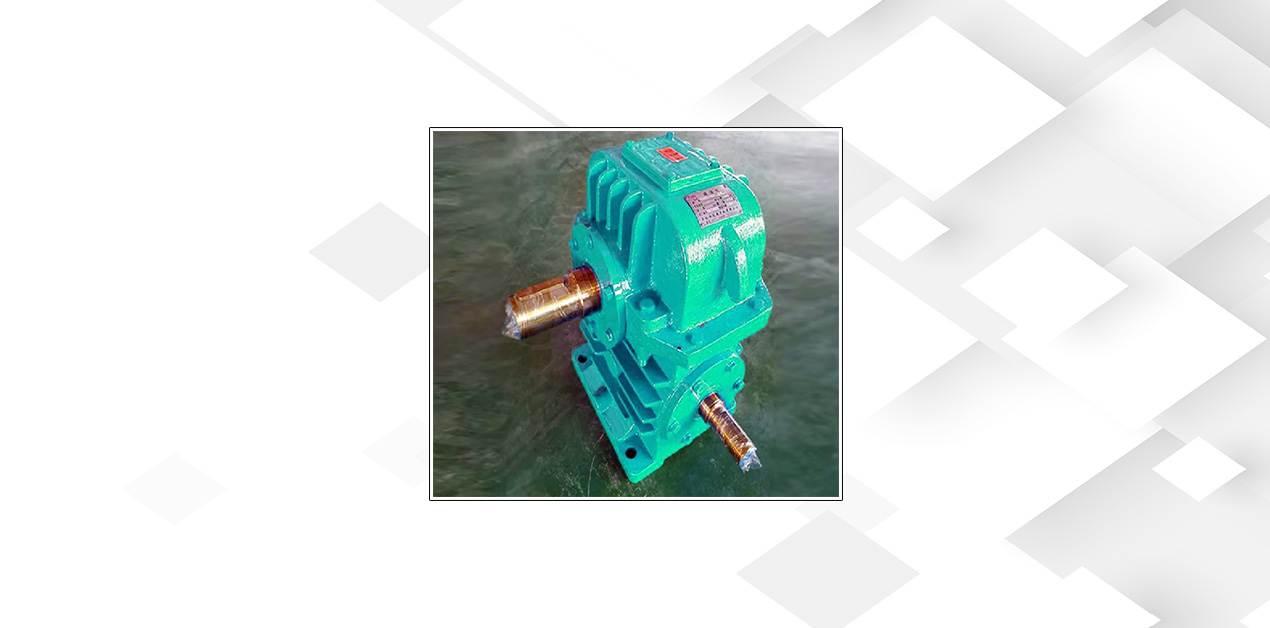

Lifting worm assembly

Lifting freely, flexible operation performance

Pate bending machine hydraulic system

Stand-alone system,easy maintenance(For hydraulic plate rolling machines)

Brand:Japan NOK

Main motor

Easy installation, easy adjustment, excellent performance, complete solutions.

Reducer

The lowest backlash.

The maximum output torque.

The highest torsion rigidity.

High efficiency high quality low noise, lift time lubrication.

High precision, long life.

Hydraulic pump

Cylinder

Hollow three-roller plate bending machine consumable parts

1.Turbine shaft: using life more than 3 years

2.Wear-resistant sleeve for shaft head:using life about 3 years

Applicable materials

Carbon steel, stainless steel, aluminum, copper, high carbon steel and other metals.

Application industry

As a mature mechanical processing equipment, the plate bending machine has been widely used in steel, construction, shipbuilding, automobile manufacturing, machinery manufacturing, power equipment manufacturing, pressure vessels, energy industry, and even aerospace and other fields.

The advantage of LXSHOW

As one of the top plate rolling machine manufacturers in the world, LXSHOW continues to lead the plate bending machine industry in the direction of intelligence, automation and environmental protection. We will use sensors, machine learning and other technologies to achieve automatic detection and automatic adjustment, improve production efficiency and product quality; through the automated control system, realize automated production of the entire production line, reduce manual operations, and reduce production costs; the plate rolling machines we produce will also be more environmentally friendly, reduce waste gas and waste water emissions, use clean energy, and reduce the effect on the environment. LXSHOW will continue to work hard to provide more high-quality and efficient products for various industries.