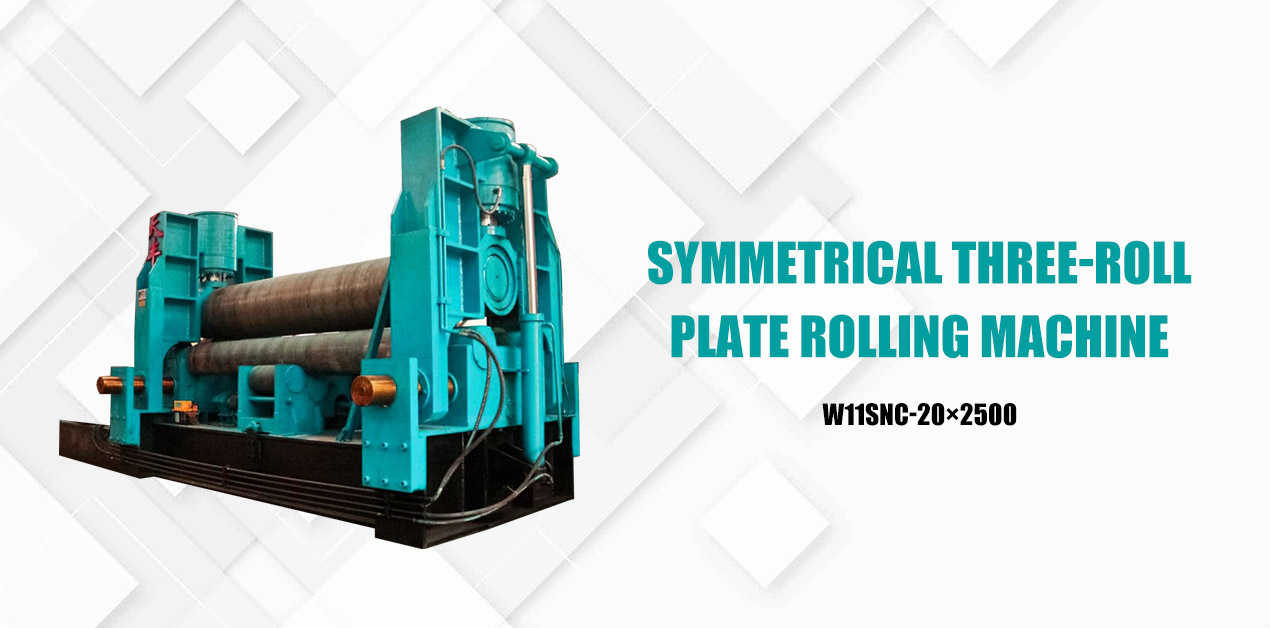

Three-roller universal cnc plate rolling machine parameters

| Model Number | W11SNC-20×2500 |

| Pressure on upper roller | 130T |

| Maximum width | 2500mm |

| Roller working length | 2550mm |

| Plate Yield Limit | δs≤245Mpa |

| Upper roll diameter | φ320 mm |

| Bottom roll diameter | Φ200mm |

| Drive speed | 4m/min |

| Symmetrical rolling | T20×B2500×Φmin800 |

| Asymmetrical rolling | T16×B2500×Φmin80 |

| Drive motor | 18.5kw |

| Hydraulic motor | 2.5kw |

| Horizontal movement motor power | 2.2 kw |

| Dimensions | 4.7×1.9×1.9(m) |

| Weight | 8.5T |

Solid work roll 45# steel

The up and down roll movement of the work roll completes the coiling action.

Screw

The screw height adjustment mechanism is a mechanism that can adjust the height through a screw.

The mechanism is composed of a screw and a nut. By rotating the screw, the nut is driven to move up and down, so as to realize the height adjustment of the working surface such as the workbench.

Electrical components

Electrical components are famous Siemens brands, which is popular in market.

Stable work ability.

Lifting worm assembly

Lifting freely, flexible operation performance

Cnc plate rolling machine hydraulic system

Ensure that there is no leakage point in static or dynamic work, and achieve stable dynamic operation without shock, crawl.

It is required that the valve group has large flow rate, small resistance, small pressure loss and low heat generation.

Main motor

Easy installation, easy adjustment, excellent performance, complete solutions.

Reducer

The lowest backlash.

The maximum output torque.

The highest torsion rigidity.

High efficiency high quality low noise, lift time lubrication.

High precision, long life.

Hydraulic pump

Cylinder

Three-roll sheet metal roller consumable parts

Turbine shaft: using life more than 3 years.

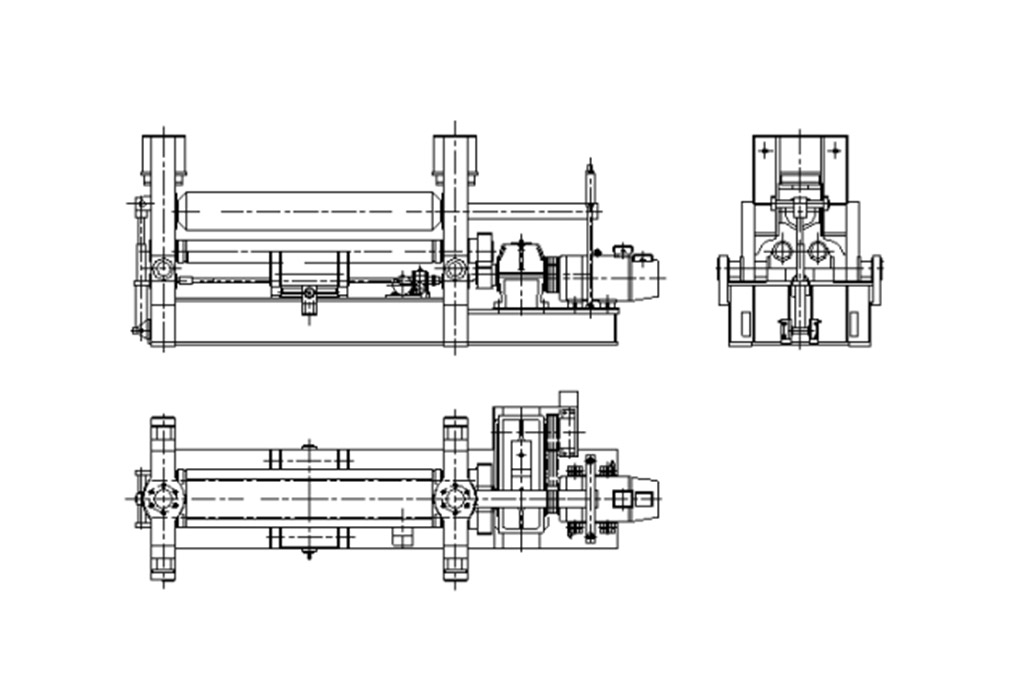

Three-roller universal cnc plate rolling machine introduction

Our plate rolling machine is a new type of cnc plate rolling machine produced based on the introduction of advanced technology at home and abroad and combined with the actual domestic situation. Because its electrical control system uses a displacement sensor and a PLC programmable controller, it can automatically detect the positions of both ends of the upper roller and monitor them in real time to ensure synchronization accuracy. Not only can products be pre-coiling and quickly rolled into shape, but it also has the characteristics of high-precision rolled products, no need for auxiliary equipment, and low investment.

The upper roller of this plate coiling machine can move vertically and horizontally. During pre-colling, the upper roller moves horizontally to make the upper roller assume an asymmetrical position relative to the lower roller. During rounding, the motor and reducer drive the two lower rollers. Since the elevation of the lower roller remains unchanged, it is convenient for feeding and operation.

Three-roller universal cnc plate rolling machine application

Applicable materials

Carbon steel, stainless steel, aluminum, copper, high carbon steel and other metals.

Application industry

As a mature mechanical processing equipment, the cnc plate rolling machine has been widely used in steel, construction, shipbuilding, automobile manufacturing, machinery manufacturing, power equipment manufacturing, pressure vessels, energy industry, and even aerospace and other fields.

LXSHOW Factory Display