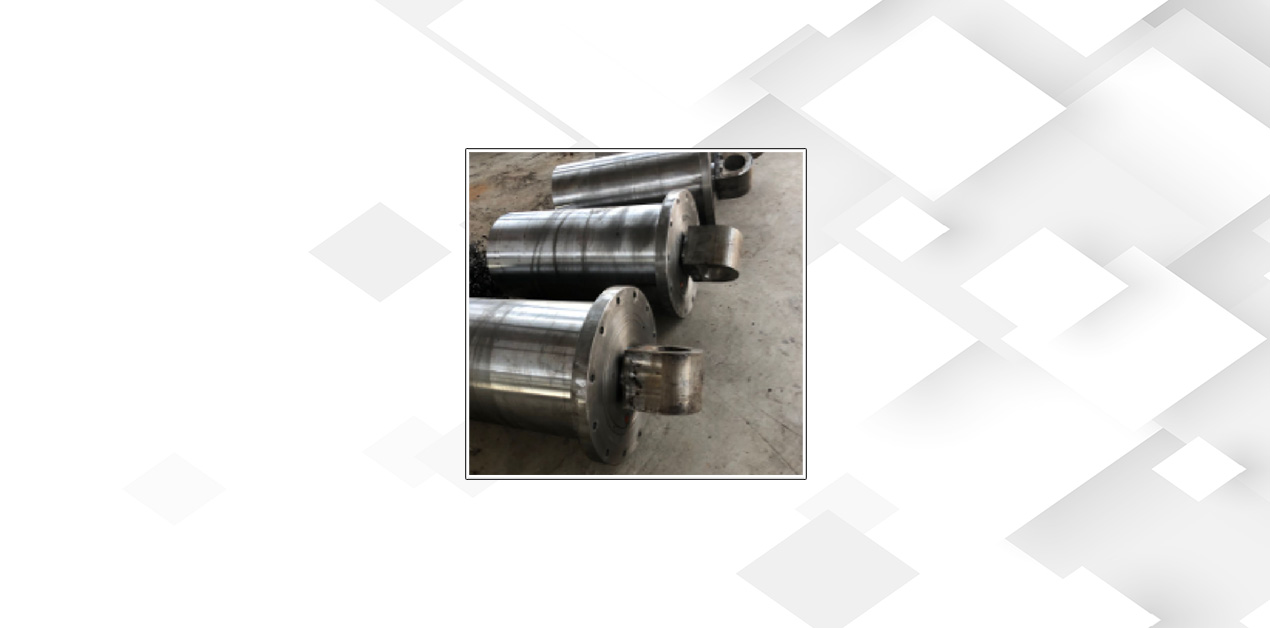

Work roll(42CrMo)

The working rolls are easy to maintain and have a long service life

Moreover, the main drive has high efficiency and saves power consumption

Classification and usage scenarios

1. Hollow roller (for thinner materials)

2. Solid roller (for thicker materials)

It is recommended to buy hollow rolls for materials below 6 thick, and the price is more affordable.

Screw

As shown in the figure, the screw on the plate rolling machine mainly plays the role of connection and fixation.

Electrical components

Brand: Siemens

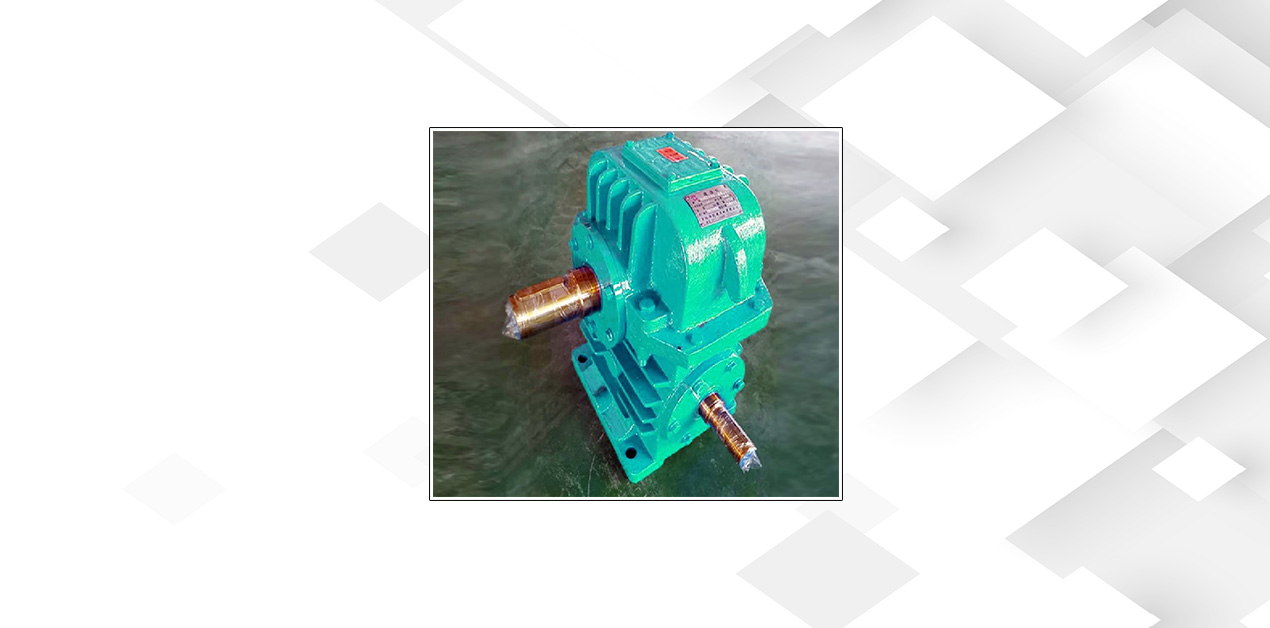

Lifting worm assembly

Rolling machine hydraulic system

Stand-alone system,easy maintenance(For hydraulic plate rolling machines)

Brand:Japan NOK

Main motor

Reducer

Hydraulic pump

Cylinder

The plate rolling machine is a kind of equipment that uses work rolls to bend and form the sheet metal. It can form parts of different shapes such as cylindrical parts and conical parts. It is a very important processing equipment.

The working principle of the plate rolling machine is to move the work roll through the action of hydraulic pressure, mechanical force and other external forces, so that the plate is bent or rolled into shape. According to the rotation movement and position changes of the work rolls of different shapes, oval parts, arc parts, cylindrical parts and other parts can be processed.

1. According to the number of rolls, it can be divided into three-roll plate rolling machine and four-roll plate rolling machine, and three-roll plate rolling machine can be divided into symmetrical three-roll plate rolling machine (mechanical)), upper roll universal plate rolling machine Machine (hydraulic type)), hydraulic CNC plate rolling machine, while the four-roller plate rolling machine is only hydraulic;

2. According to the transmission mode, it can be divided into mechanical type and hydraulic type. Only the hydraulic type has an operating system, and the mechanical plate rolling machine does not have an operating system.

Carbon steel, stainless steel, aluminum, copper, high carbon steel and other metals.

Its three rollers are all solid forged rollers, and have been tempered and quenched. The upper roller can move horizontally and up and down, and the plate can be rolled down by vertically moving up and down of the hydraulic cylinder. It can also be rolled horizontally. Move, pre-bend the straight edge of the sheet to achieve a better rounding effect.

The middle of the upper roller is in the shape of a drum, and a set of supporting rollers at the front and rear of the lower roller jointly solve the problem of bulging in the middle of the reel. The lower roller is the main rotating roller, and the lower roller is driven to rotate by the motor reducer. Equipped with hydraulic tipping, the tipping cylinder can be tilted down to take the workpiece more convenient and labor-saving. The machine is equipped with plc programmable display control, and the digital operation is easy to learn.

The upper roll universal plate rolling machine is the most advanced model in the three-roll plate rolling machine. It is very suitable for rolling thick plates, and can be 120mm, 140mm, 160mm.

1. The upper roller is lifted up and down by the oil cylinder, and the main structure is welded by H-shaped steel on both sides.

2. The side rollers are powered by two sets of oil cylinders, and the roller frames on the brackets are determined according to different commonly used diameters.

3. Internal components: The hydraulic motor is connected to the reducer, the hydraulic valve group is below, the main motor is next to it, and the electrical cabinet is behind.

The upper roller universal plate rolling machine has dual functions of pre-bending and rolling, and there is an extra lower drag roller, driven by hydraulic drive;

The mechanical plate rolling machine has no pre-bending function, the drive is a motor-driven gearbox, and the gearbox drives the lower roll.

Three roll plate rolling machine vs four roll plate rolling machine

The three-roll plate bending machine is a manual unloading method, which requires manual unloading of the processed workpiece.

The four-roll plate rolling machine is controlled by buttons, which is convenient and quick to unload, and it is much safer than the three-roll plate rolling machine.

Pre-bending method

The upper roller universal plate bending machine is pre-bent by the upper roller, and the upper roller can be pressed down or moved horizontally. Its disadvantage is that translation takes a certain amount of time, and the efficiency is slightly lower.

The four-roll plate rolling machine is pre-bent by lifting the side rolls, and the speed is very fast, especially the advantage of pressing the plate below 20 mm is more obvious.

Control method

The lower roller of the upper roller universal plate rolling machine is fixed, and it lacks a positioning ruler when rolling and feeding, and requires manual measurement and calibration, so it cannot realize numerical control, and can only be called digital display or simple numerical control.

When the four-roller plate rolling machine is feeding, the side roller is used as a guide, the system is controlled and the positioning is accurate, which makes it realize the numerical control and has the function of one-key rolling.

1. The texture of the material you use?

2. Material thickness and width?

3. Minimum roll diameter (inner diameter)?

1.Our three rolls are all made of superior forged circles, which are rough processed, quenched and tempered, finished, and quenched. The material is durable and has high surface hardness. Compared with ordinary round steel or even hollow rolls used in other areas, It is not the same product.

2.The chassis and wall panels of our plate rolling machine are processed as a whole after welding and forming. The materials are abundant and high-precision, and the welding process of loose parts is not used.

3.As for accessories, the motors and reducers of our plate rolling machine are all locally produced high-quality products, and the electrical appliances are Siemens, with stable overall performance, low failure rate and long service life.