Metal pipes are often used in aerospace, construction machinery, automobile industry, petrochemical, agricultural and animal husbandry machinery and other industries. It is necessary to process metal pipes into parts of different shapes and sizes to meet the requirements of different working scenarios. The tube laser cutting machine is particularly suitable for processing various metal pipes. High flexibility and high automation are the characteristics of the tube laser cutting system, which can realize the production mode of different materials in small batches and multiple varieties.

The following will introduce the key technology tube laser cutting system.

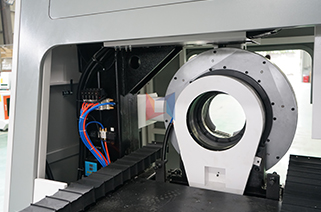

Light guide focusing system

The function of the light guide focusing system is to guide the light beam output by the generator to the cutting head of the focusing light path. For laser cutting pipes, the focused spot diameter of the focused beam is small and the power is high to obtain high-quality slits. This requires the generator of the to output low-order modes. When the laser cutting machine tube cuts the tube, in order to make the beam focus diameter smaller, the order of the transverse mode of the laser should be small, preferably the fundamental mode. The cutting head of the pipe fiber laser cutting machine is equipped with a focusing lens. After the laser beam is focused by the lens, a smaller focusing spot can be obtained, so that high-quality pipe cutting can be carried out. To

Trajectory control of cutting head

When the fiber laser tube cutting machine cuts the pipe, the shape of the pipe is relatively complicated and belongs to the space surface. It will be difficult to program and process with conventional methods. This requires the operator to select the correct processing path and appropriate reference points according to the processing requirements. The numerical control system records the feed situation of each axis and the coordinate value of the reference point, and then uses the spatial straight line and arc interpolation function of the fiber laser cutting machine for steel tube system to record the coordinate value of the processing process and generate the processing program.

Automatic control of focus position

An important factor affecting cutting quality is the focal position. It is one of the key technologies for laser cutting pipes to make the vertical direction of the focal point relative to the surface of the workpiece unchanged through automatic measurement and control devices. Through the integration of the laser focus position control and the laser processing system linear axis (XYZ), the movement of the cutting head is lighter and more flexible, and the position of the focus point can be fully understood, avoiding the cutting head and cutting pipe or tube during processing. Other objects collide.