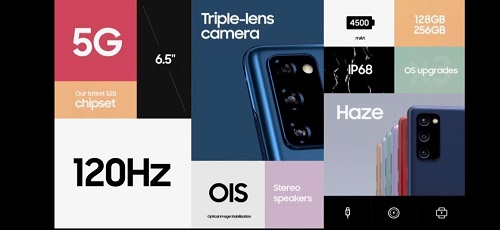

At 10 pm on September 23, Samsung Electronics held the Galaxy S20 FE global online conference, officially releasing the new member of the Galaxy S20 series, the Galaxy S20 FE. "FE" is the abbreviation of "Fan Edition". Like the Galaxy S20, the Galaxy S20 FE uses a hole-digging screen solution. Samsung "Galaxy Unpacket for Every Fan" officially released.

So, what are the applications of fiber laser cutting machine in the mobile phone industry?

1. Mobile phone screen panel cutting

Galaxy S20 FE does not use Samsung’s usual curved or micro-curved screen design. Instead, it returns to the straight screen. Compared with other members of the Samsung Galaxy S20 series, although the Galaxy S20 FE also uses a front punch design, The straight screen design is still very eye-catching. You must know that the S20 series uses hyperboloid screens. There is a good distinction between the two in terms of screen design.

Fiber laser cut is the best processing equipment for special-shaped cutting of the full screen of mobile phones. Laser cutting is a non-contact processing method, which will not cause the cutting material to be damaged by mechanical stress. The processed workpiece has a small heat-affected zone, small thermal deformation of the workpiece, and a small amount of subsequent processing. Moreover, the laser sheet metal cutter is highly efficient and easy to guide. It can realize the transformation of various directions through focusing. It is very easy to cooperate with the numerical control system. It is an extremely flexible cutting method for processing complex workpieces.

2. Camera protective film cutting

Samsung Galaxy S20 FE is equipped with a professional rear camera combination and a 32-megapixel front camera, allowing users to capture wonderful and unforgettable moments with high image quality anytime, anywhere. Thanks to the large image sensor and AI multi-frame synthesis technology, users can take delicate and moving photos or videos even in low light environments.

Most of the mobile phone camera protective film uses sapphire material, which has better scratch resistance and higher hardness than glass. This hardness also makes ordinary mechanical processing unable to efficiently cut it, while laser steel cutting machine is not affected by hardness and brittleness. The impact of the high-speed and high-quality split processing can be completed.

3. Circuit board FPC cutting

With the promotion and development of 5G technology, the mobile phone industry will undergo tremendous changes in the trend of new technological changes, from materials to manufacturing processes, and core components such as chips, terminal antennas, and circuit boards will be further refined. As a non-contact processing tool, the precision laser cutting machine for metal sheet has a unique advantage in the FPC flexible circuit board cutting process. It does not need to make an etching knife, and can quickly complete the production of samples and shorten the product production cycle.

Advantages of precision cnc fiber laser cutting machine:

1. It is widely used in industries such as electronics, electrical appliances and other precision machinery and hardware, 3C industries.

2. The marble working platform is adopted, and the screw drive ensures long-term stable operation.

3. Adopt fully enclosed motor.

4. Optional camera automatic positioning device.

5. With camera positioning function.

This phone will be available for pre-orders worldwide from Wednesday and will be sold in stores on October 2. According to Korean media TheLec, Samsung Electronics stated that its Samsung Galaxy S20 FE production plan is 10 million units.