Stainless steel is widely used in industrial production and can be found everywhere in the kitchen, such as gas stoves, microwave ovens, electronic components of gas stoves, kitchen hardware, etc. in the kitchen. The advantages of stainless steel are high temperature resistance, easy care and durability. The fiber metal sheet laser cutting machine can perform plane cutting, pipe cutting, punching and other forms of processing on stainless steel, which can fully meet the processing needs of stainless steel supplies.

However, it is not difficult to find that after careful observation, in addition to household appliances, small hardware, etc., stainless steel cabinets rarely appear in ordinary people's homes, and more often appear in the back kitchen of the restaurant, which limits the sales of stainless steel cabinets.

Compared with traditional wooden cabinets, the advantages of stainless steel cabinets are very obvious. The true zero formaldehyde, the countertop is integrated, will not crack, not afraid of fire or water, good impact resistance, strong hardness, no discoloration, easy to clean, recyclable.

Among the many benefits, stainless steel cabinets are still unable to enter ordinary people's homes. The reason is expensive and the purchase cost is high; the reason is "low value".

To solve the two disadvantages of stainless steel cabinets, the use of more advanced small fiber laser cutting machine metal for processing is the common choice of many manufacturers.

Common stainless steel cutting methods include high-pressure water jet waterjet water cutting, progressive punching, guillotine shears, disc shears, grinding wheel cutting, laser cutting, etc. Among them, the proportion of stainless steel sheet laser pipe cutting machine fiber in industrial production, stainless steel cabinets mostly use 1-2mm stainless steel sheet.

In the processing of metal sheet, compared with the traditional processing technology, 6kw fiber laser cutting machine has obvious advantages. The laser beam transposition time is short, which can complete continuous processing. The use of laser cutting not only has fast processing speed and high efficiency, but also can complete any shape of fiber laser cutting machine cover, which can effectively reduce the processing cost of stainless steel cabinets and help enterprises occupy the market with more cost-effective products.

In terms of aesthetics, the laser beam of the fiber laser cutting machine for stainless steel is concentrated in a small area. Due to the very concentrated energy, only a small amount of heat is transferred to other parts of the steel, resulting in little or no deformation, so the processing accuracy is high and the cross section Smooth, without stress deformation, the processed stainless steel plate has a higher "face value".

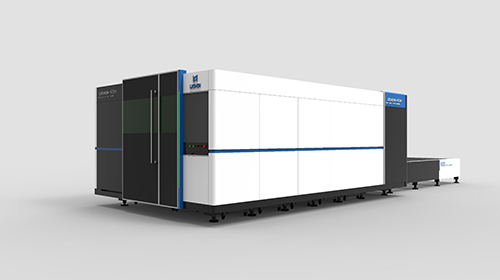

The ingenuity quality of LXSHOW laser cutting machine metal fiber helps the production of stainless steel cabinets.

Highest maintenance cost: The equipment is independently manufactured with core light sources, maintenance and repair costs, and procurement costs are reduced by 20%.

Higher cost performance: The equipment uses an extended cutting process library, which has the same cutting efficiency and cutting quality as imported lasers.

Restart cutting speed: the cutting speed is as fast as 80m / min, and the acceleration is 1.5G.

Higher processing efficiency: up to 6m * 2.55m cutting width, to meet the horizontal placement of multiple 1.25 * 2.5m boards, significantly improve cutting efficiency.