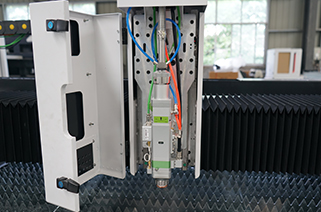

The composition of the laser cutting head of the metal fiber laser cutting machine

Collimation component: Converge the divergent light transmitted from the optical fiber, and straighten or collimate it.The collimation component also includes a collimation centering part and a water cooling part.

Focusing component: It is placed in the body to focus the collimated parallel laser beam. The focus position can be changed through the focusing part of the focusing component to meet the needs of laser iron sheet cutting machine for cutting different materials and different thickness plates.

Protective mirror box: used to isolate the outside world from the internal optical path of the cutting head of the brass cutting laser machine, ensuring the sealing of the optical path, preventing dust and impurities from entering the optical path, and extending the service life of the fiber cutting head.

Sensor and control box: The distance between the cutting head and the surface of the workpiece can be kept stable for a long time and reliably, providing a guarantee for obtaining the best cutting quality.

Cutting nozzle: installed at the front end of the cutting head, it is the m channel for the laser beam and the auxiliary gas. The auxiliary gas forms a high-speed air flow after passing through the cavity of the cutting nozzle. Blow away the molten material to achieve the purpose of cutting.

Maintenance of laser cutting head

♦ Use a brush to clean the dust before going to get off work, and then clean the entire surface of the cutting head of the fiber laser cutting machine for metal with a small amount of alcohol with a dust-free cloth (please note that you cannot use air blowing).

♦ Before cutting the cnc metal laser cutting machine, check whether the light comes out of the center of the nozzle, otherwise, please re-adjust and calibrate.

♦ Check the roundness and cleanliness of the nozzle before cutting, and clean the nozzle.

♦ Check whether the protective lens of the fiber laser cutting machine sheet metal is clean every day, otherwise, please clean the protective lens with isopropanol or analytical alcohol (alcohol content above 99.5%), clean and clean without leaving water marks.

♦ Check the ceramic ring, SMA wire, SMA pin, and preamplifier every day for looseness and foreign matter. Please tighten and clean.