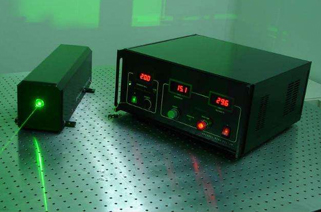

Laser splitter laser is an important part of laser drilling equipment. Its main function is to convert the electrical energy provided by the power supply system into laser energy with a certain conversion efficiency. The so-called laser cutting of laser cutting machine refers to the energy released when the laser beam is irradiated to the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. It has high precision, fast cutting, not limited to cutting patterns, and automatic layout saves The characteristics of materials, smooth cuts and low processing costs will gradually improve or replace traditional metal cutting process equipment. According to the nature of laser working material, it can be divided into gas laser and solid laser. The gas lasers used for drilling mainly include carbon dioxide lasers, while the solid lasers used for drilling mainly include ruby lasers, neodymium glass lasers and YAG lasers.

The machine tool for laser drilling is a simple and universal form of a three-dimensional machine tool. Two-dimensional motion is at the horizontal

X and Y indicate that the two coordinate axes are perpendicular to each other, and the third dimension Z axis is perpendicular to the Z-Y plane. Each dimension can drive the ball screw through the stepping motor to run on the linear ball guide, its accuracy is determined by the accuracy of the screw and the accuracy of the ball guide. If equipped with a microprocessor system, the three-dimensional machine tool can complete the laser processing of various holes in the plane and group holes within a certain range. When it is necessary to process a series of holes in a pipe or barrel material, the machine tool should have a five-dimensional function. In addition to the aforementioned three-dimensional, the added two-dimensional is the 360-degree rotation of the XY plane. We define it as the A axis, XY The plane is inclined at 0-90 degrees in the Z direction, and we define it as the B axis. With such various types of laser drilling, the five-dimensional worktable is competent. When the equipment investment needs to be saved, the CNC of the B axis can be changed to manual. This can save money and basically complete all drilling tasks. In recent years, the level of laser drilling machines at home and abroad is at a stage of rapid development. The laser output power is gradually increasing, the pulse width is getting narrower and narrower, and the frequency range As it gets wider and wider, other parameters also become more and more conducive to the development of drilling. The flexibility of the control part of the light guide system and the laser punching machine has been continuously improved, making the punching range continuously expanding. At present, there are dozens of types of laser drilling machines in China. In addition to colleges and scientific research institutes, companies specializing in manufacturing laser equipment are gradually increasing. This shows that China's laser processing is developing in the direction of industrialization.

CO2 laser has many unique advantages, its conversion efficiency is higher than other lasers, and it can be absorbed by many non-metallic materials (such as organic glass materials, plastics, wood, multilayer composite plates, quartz glass materials, etc.). More importantly, compared with other lasers, carbon dioxide lasers can output high power. When combined with other technologies, high-speed drilling can be achieved, with a maximum speed of 100 holes/second, which is difficult for other lasers to achieve.

Despite this, due to the inconvenient focus and dimming of the CO2 laser, the one-time investment of the equipment is relatively large, and it is not as common in laser drilling equipment as the other three lasers. The so-called laser cutting of laser cutting machine refers to the energy released when the laser beam is irradiated to the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. It has high precision, fast cutting, not limited to cutting patterns, and automatic layout saves The characteristics of materials, smooth cuts and low processing costs will gradually improve or replace traditional metal cutting process equipment.

Solid laser is widely used in laser drilling with its unique advantages. Its main advantages are:

(1) The output wavelength is short. The so-called laser cutting of laser cutting machine refers to the energy released when the laser beam is irradiated to the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. It has high precision, fast cutting, not limited to cutting patterns, and automatic layout saves The characteristics of materials, smooth cuts and low processing costs will gradually improve or replace traditional metal cutting process equipment. A

(2) The light output can be transmitted by ordinary optical materials. The so-called laser cutting of laser cutting machine refers to the energy released when the laser beam is irradiated to the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. It has high precision, fast cutting, not limited to cutting patterns, and automatic layout saves The characteristics of materials, smooth cuts and low processing costs will gradually improve or replace traditional metal cutting process equipment.

(3) The whole machine is small in size, easy to use and maintain, and its price is lower than that of a carbon dioxide laser. The laser cutting machine is concentrated into a high-density beam in the form of light. The beam is transmitted to the work surface to generate enough heat to melt the material, and the high-pressure gas coaxial with the beam directly removes the molten metal to achieve the purpose of cutting. Explain that laser cutting is essentially different from machine machining