Advantages of picosecond laser glass cutting machine

Compared with CNC processing equipment, the fragile material non-taper picosecond laser cutting machine has no consumables, no pollution, and high production efficiency (several times the processing efficiency of CNC) during the production process, which greatly saves production and manufacturing costs for processing manufacturers. , Improve product profit.

Application of Picosecond Laser Glass Cutting Machine

1. Strengthened and non-strengthened glass cutting, such as: mobile phone glass cover, car glass cover, camera glass cover, etc.;

2. Sapphire glass cutting, such as: mobile phone sapphire cover, camera sapphire glass cover, sapphire light bar (LED light bar), etc.;

3. LCD screen glass cutting, such as: special-shaped LCD screen inverted R/U/C angle, LCD screen slitting, etc.;

4. Other optical glass cutting, such as: filter cutting, mirror cutting, etc., prisms;

Parameters of Picosecond Laser Glass Cutting Machine

| Power | 50W (optional 10W, 30W, 50W, 75W, 100W and above) |

| Wavelength | 1064nm, beam quality: M2<1.3 |

| Pulse length | <10PS; Pulse frequency: 1Hz-1000kHz |

| Cooling method | Water cooling |

| Focus spot | <2um |

| Cutting speed | 0-300mm/s adjustable |

| Cutting thickness | ≤10mm (different materials may affect the processing thickness, thicker can be cut by multiple cutters) |

| Minimum cutting edge chipping | <5um |

| Cutting accuracy | ≤±20um, the highest precision of equipment cutting is ±5um |

| X/Y cutting stroke | 450mm x600mm, single platform (360X400 single head dual platform optional, 500mmX600mmSingle head double platform, 600x700 cutting + split double platform) |

| X/Y moving speed | Maximum 1000mm/s, acceleration 1G |

| X/Y positioning accuracy | ≤±2μm |

| X/Y repeat positioning accuracy | ≤±1um |

| Z axis travel | 50mm |

| Z-axis focus positioning resolution | 1um |

| Precision | ≤±3μm |

| Voltage, power | AC220V±5%,L+N+E , <4KW |

| Ambient temperature | 18-28℃ |

| Relative humidity | 10-70% (on the principle of non-condensing), clean environment |

Parts of Picosecond Laser Glass Cutting Machine

1. Laser:

Picosecond pulse laser (the seed sources are all the world's mainstream brands such as Germany Nlight)

2. Cutting head

Exclusive glass cutting head, all lenses imported from the United States, fine spot, long focal depth, minimum focal spot <2um, focal depth length up to 15mm;

3. Countertop

The motor platform and the base of the optical platform are made of natural marble, and the precision level reaches 00 after the second fine grinding process.

4. Drive system

X/Y axis motor adopts high-end linear motor, German 0.1um digital grating ruler, Taiwan screw and guide rail, high-quality core motion

Components, 24 hours operation without failure;

5. Adsorption system

Adopt high negative pressure vacuum pump to absorb products to ensure positioning stability;

6. Visual positioning system

Equipped with 5 million CCD and telecentric vision lens, ring-shaped brightness adjustable light source, accurate identification of Mark points such as circle and cross;

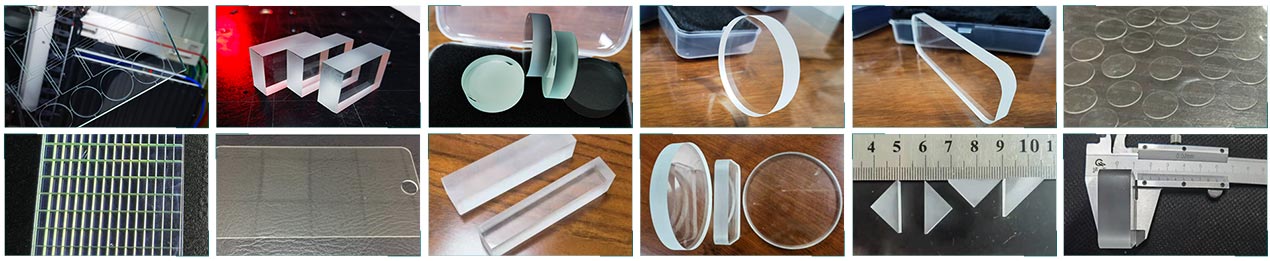

Sample of Picosecond Laser Glass Cutting Machine