Application

Applied materials and Industry:

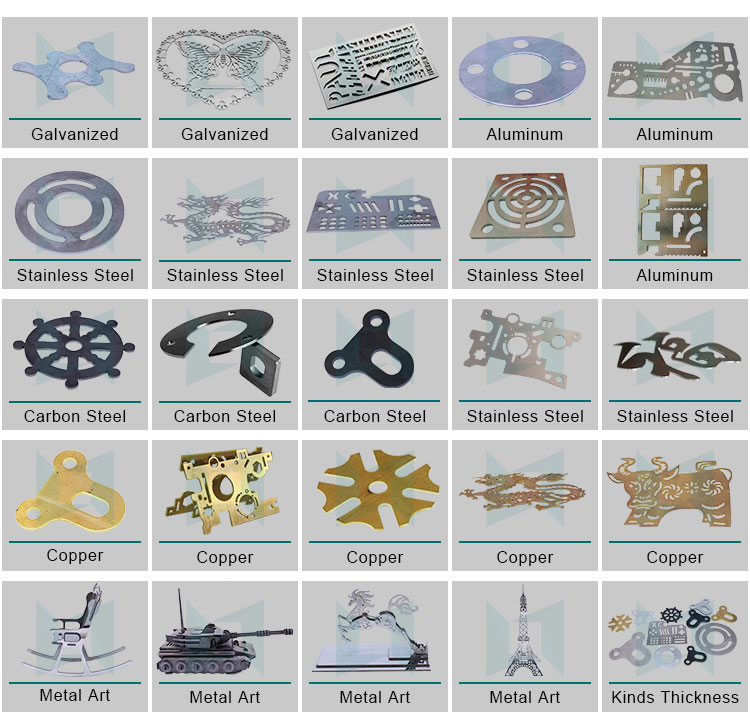

Applied materials of small laser metal cutting machine:

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Applied industry of mini fiber laser cutting machine:

Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

| Machine Model | LXF0640 |

| Power of Generator | 500/750/1000/1500W(optional) |

| Transmission Mode | Grinding Precision Screw Transmission |

| Working Area | 600*400mm |

| Repeated Positioning Accuracy | ±0.006mm |

| Max Running Speed | 40m/min |

| Max Acceleration | 0.5G |

| Specified Voltage And Frequency | 220V 50/60HZ |

Key Advantages

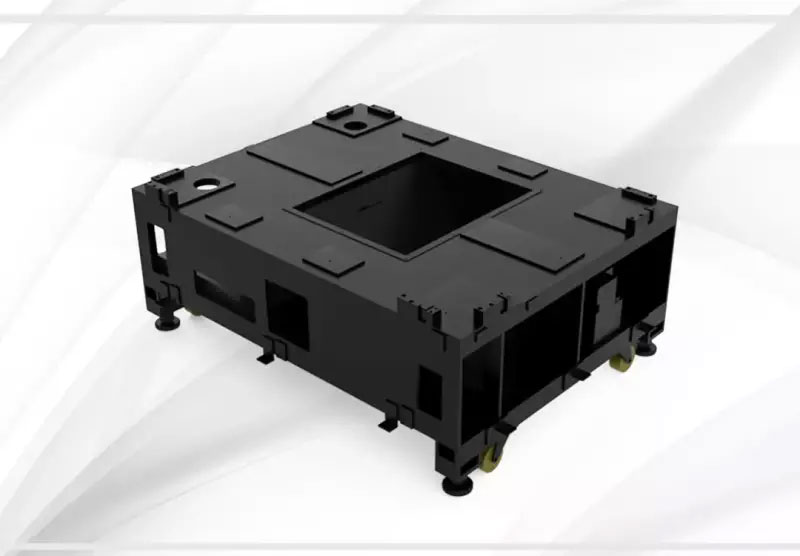

1 Strong stability, high precision, 20 years without deformation

Adopted carbon structural steel with good toughness, ductility, welding performance and thermal processing;Stress annealing and vibration aging treatment eliminate the stress in welding and processing of machine bed, the machine bed precision is long-lasting.

2 Dual Rail and Dual Driver Design

To prevent the cutting line deformation caused by the Y-axis screw bending, the Y-axis on both sides have been equipped two rails guide and double ball drive screw design to ensure the straightness and arc degree when with high-speed cutting is in operation.

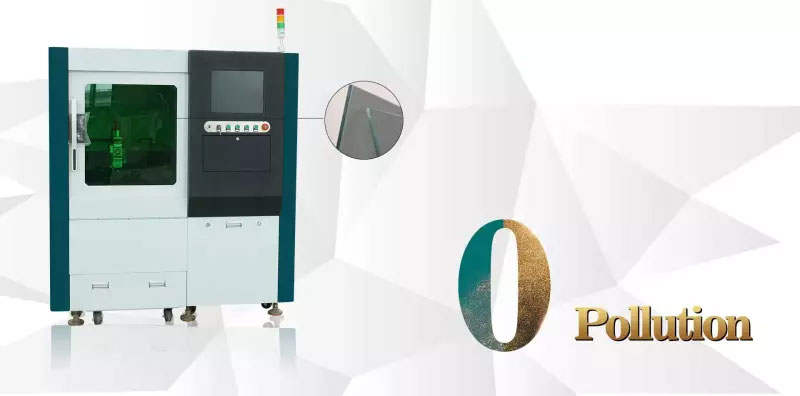

3 Safety and No Pollution

• With a fully enclosed design;

• The observation window adopts an European CE Standard laser protective glass;

• The smoke produced by cutting can be filtrated inside, it's non-polluting and environmentally friendly;

4 Cast aluminum crossbeam

After artificial aging, solution treatment and finishing, crossbeam owns good integrity, rigidity, surface quality, toughness and ductility. Aluminum alloy’s metal characteristics of light weight and strong rigidity are helpful to high speed movement in processing, and high flexibility is beneficial to high-speed cutting of various graphics based on high accuracy.

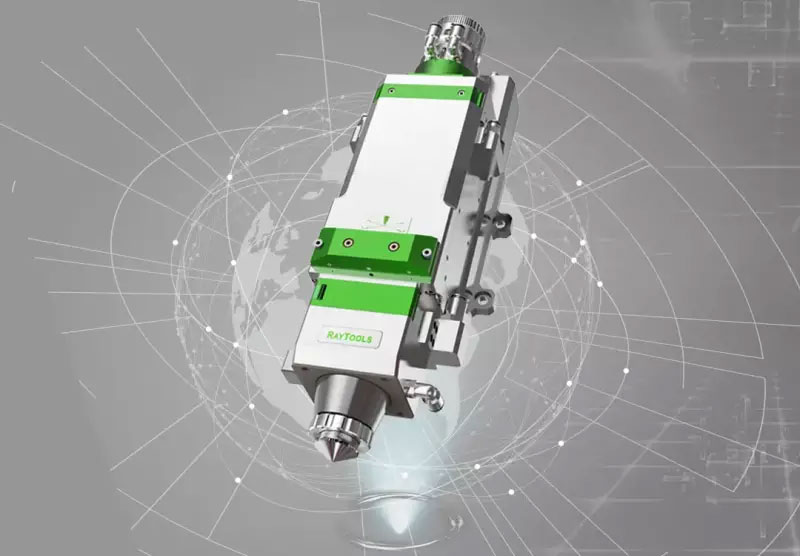

5 Intelligent Autofocus

The high efficiency cooling:

Collimating lens and focus lens group are cooling structure, increase cooling airflow nozzle at the same time, the effective protection of nozzle, the ceramic body, prolonged work time.

Chase the light aperture:

Through the pore diameter of 35 mm, effectively reduce the stray light interference, ensuring cutting quality and service life.

Automatic focus:

Automatic focus, reduce human intervention, focusing speed 10 m/min, repeat accuracy of 50 microns.

25 mm carbon steel sheet pre punch time < 3 s @ 3000 w, greatly improve cutting efficiency.