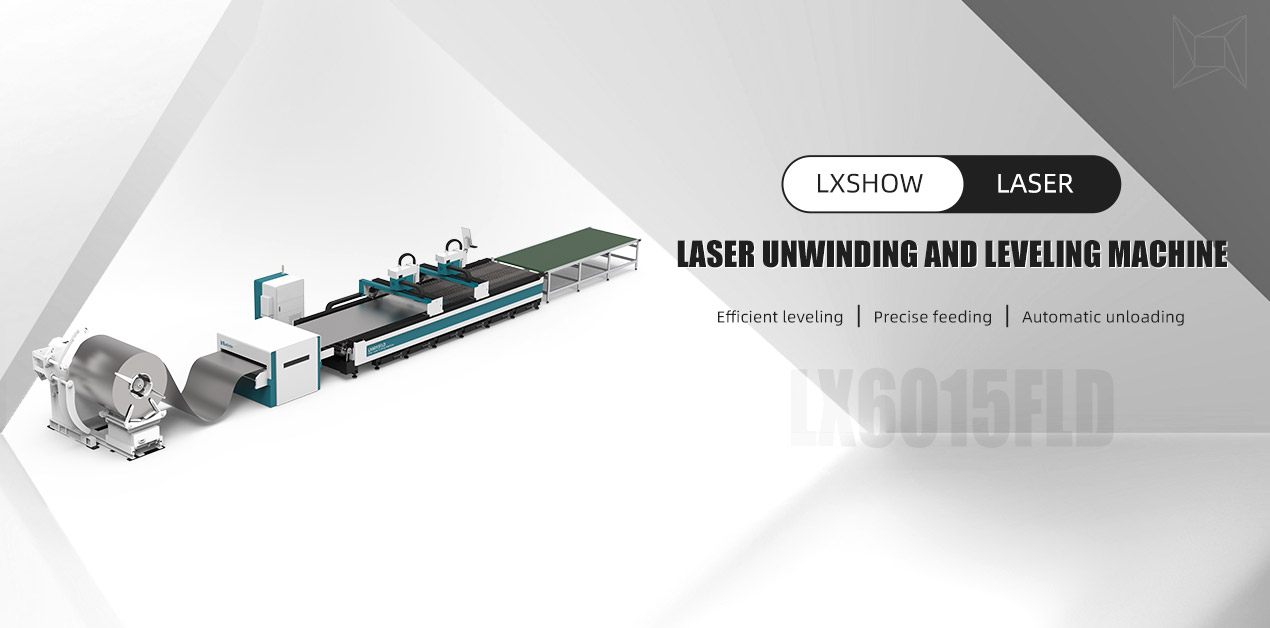

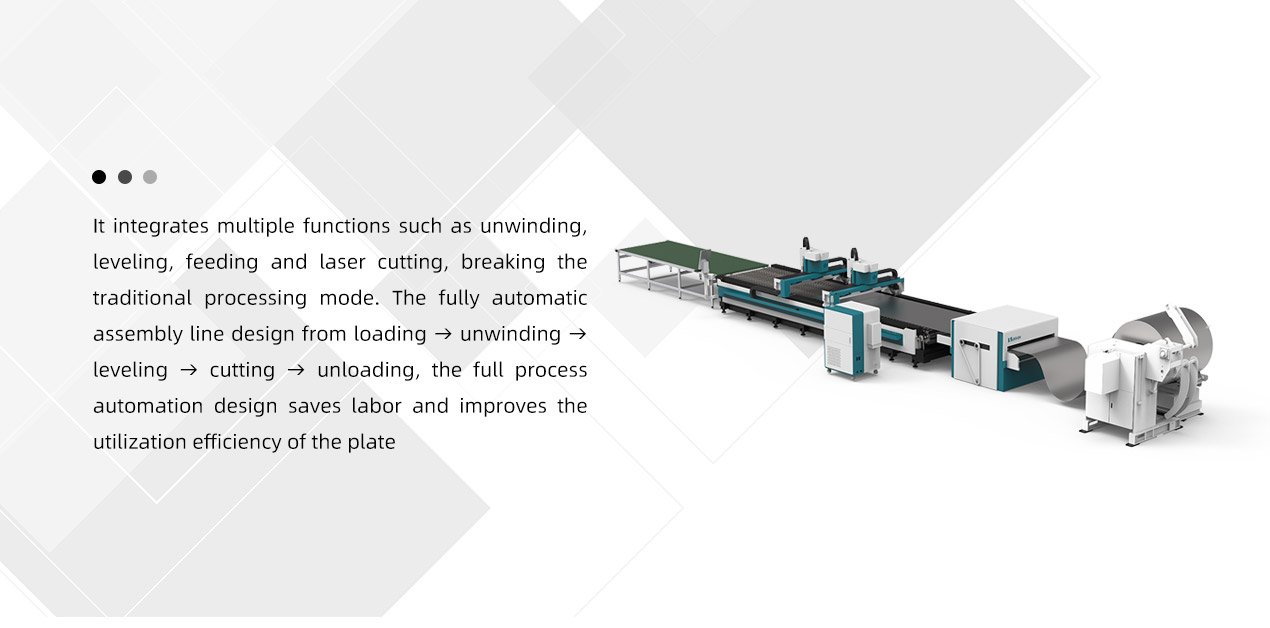

It integrates multiple functions such as unwindingleveling, feeding and laser cutting, breaking thetraditional processing mode. The fully automaticassembly line design from loading ->unwinding →>leveling → cutting → unloading, the full processautomation design saves labor and improves theutilization efficiency of the plate

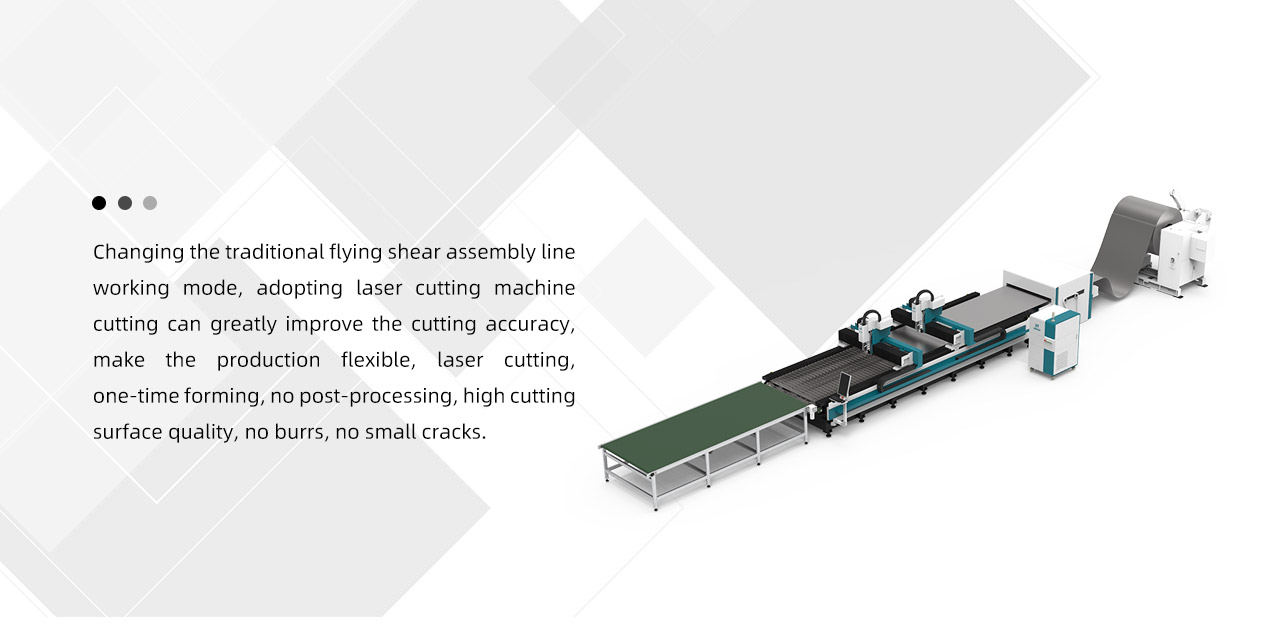

Changing the traditional flying shear assembly lineworking mode, adopting laser cutting machinecutting can greatly improve the cutting accuracy,make the production flexible,laser cutting,one-time forming,no post-processing, high cuttingsurface quality, no burrs, no small cracks.

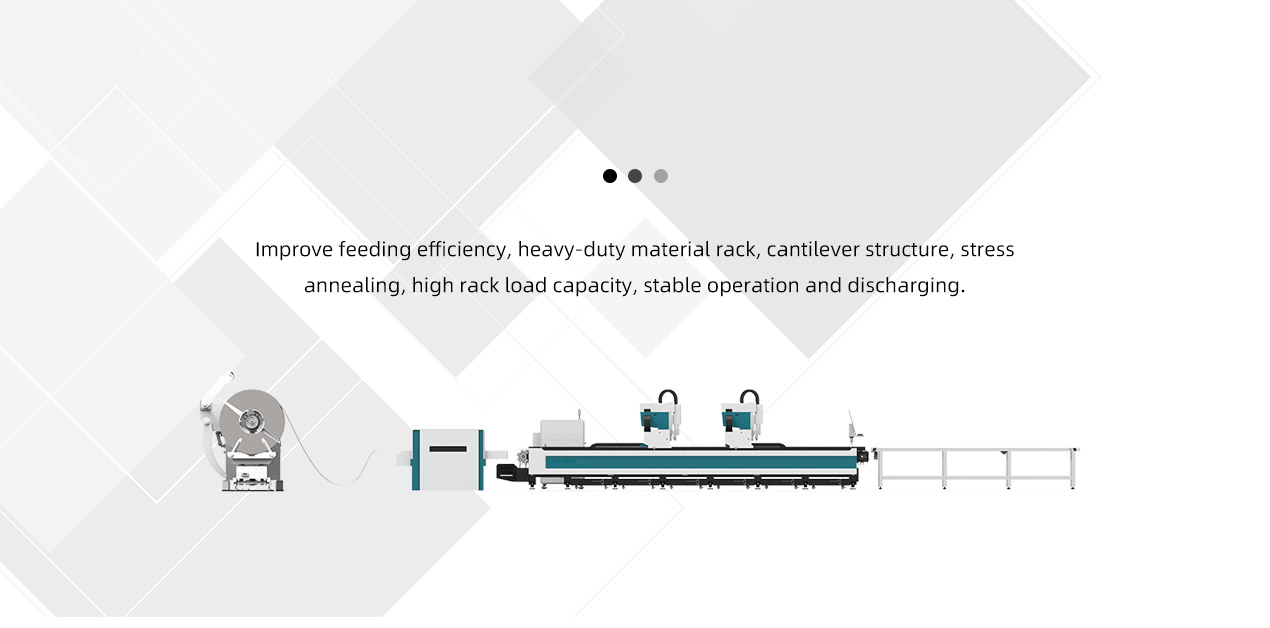

lmprove feeding efficiency, heavy-duty material rack, cantilever structure, stressannealing, high rack load capacity,stable operation and discharging.

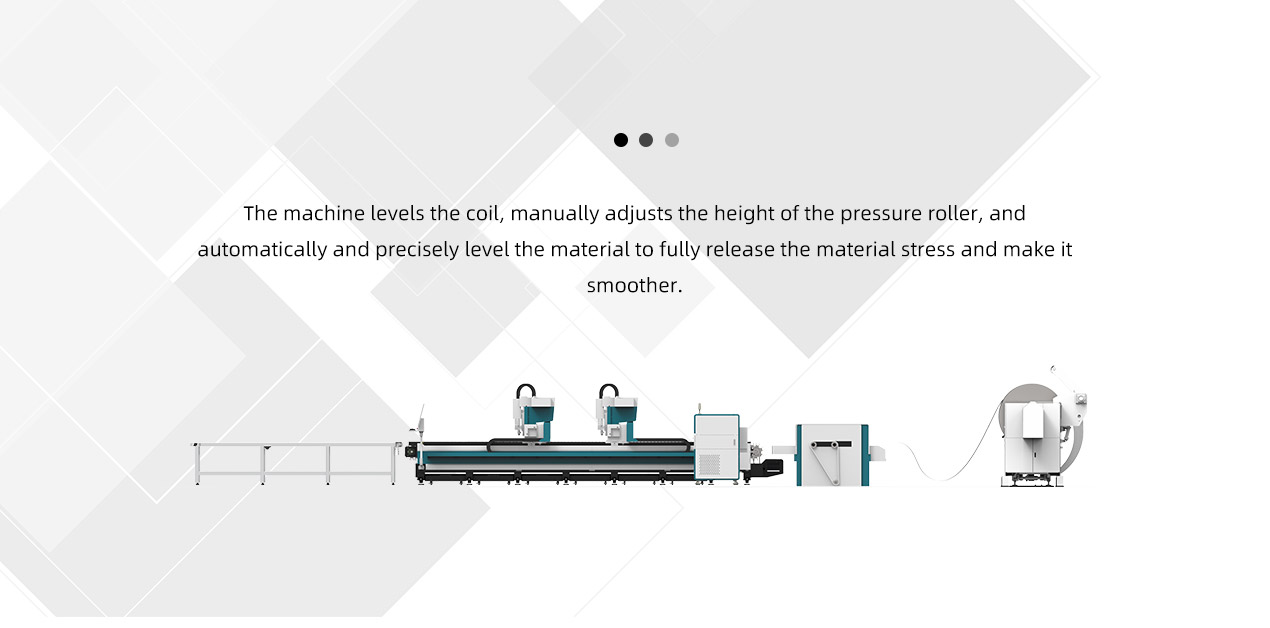

The machine levels the coil, manually adjusts the height of the pressure roller, andautomatically and precisely level the material to fully release the material stress and make it smoother.

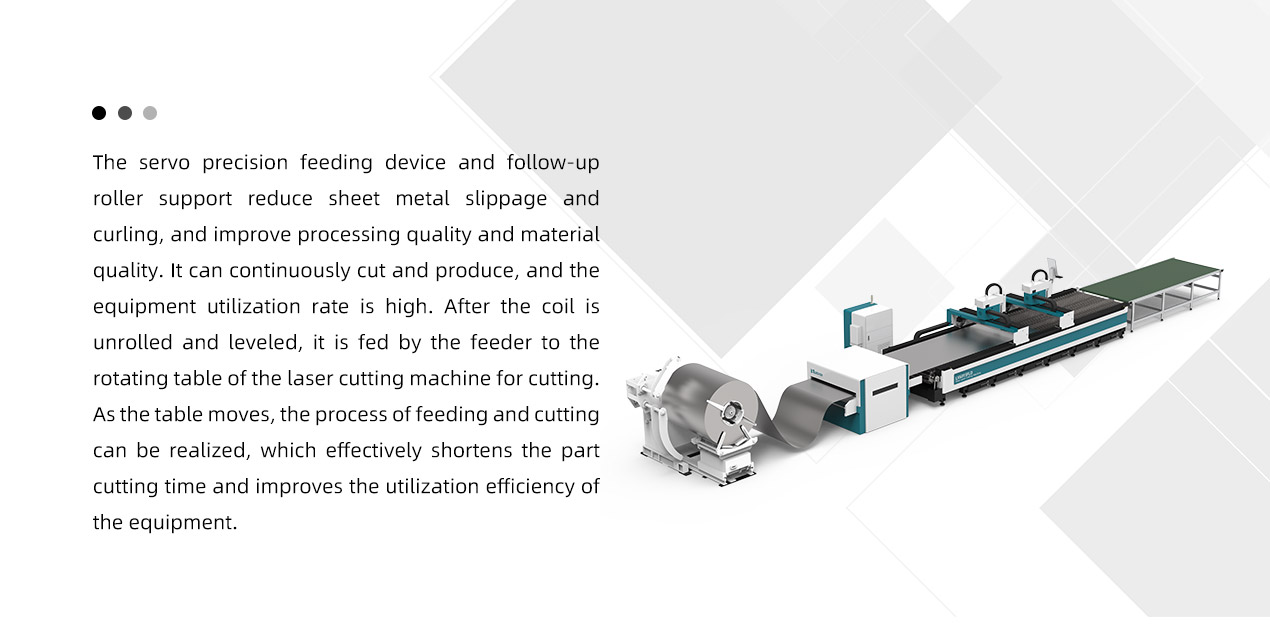

The servo precision feeding device and follow-uproller support reduce sheet metal slippage andcurling, and improve processing quality and materialquality. it can continuously cut and produce, and theequipment utilization rate is high. After the coil isunrolled and leveled, it is fed by the feeder to therotating table of the laser cutting machine for cutting,As the table moves, the process of feeding and cutting can be realized, which effectively shortens the partcutting time and improves the utilization efficiency ofthe equipment.

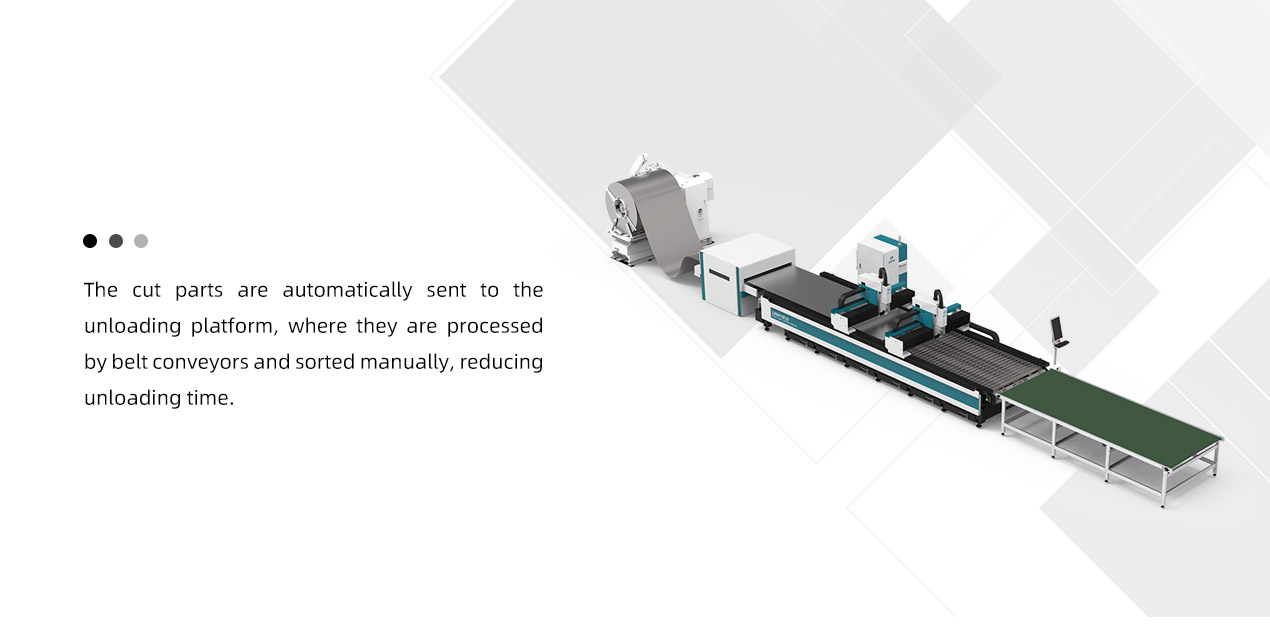

The cut parts are automatically sent to theunloading platform, where they are processedby belt conveyors and sorted manually, reducingunloading time.