| Power of Generator | 3000W (Optional powers: 1000W, 1500W, 2000W, 3000W, 4000W,6000W) |

| Working Area | 1500*3000mm |

| Laser Generator | Raycus |

| Laser Wave Length | 1064nm |

| Working Table | Sawteeth |

| Maximum Idle Running Speed | 120m/min |

| Maximum acceleration | 1.5G |

| Positioning Accuracy | ±0.02mm/m |

| Repeated Positioning Accuracy | ±0.01mm |

| Cutting Thickness | Carbon steel:≤22mm;Stainless steel:≤10mm |

| Control System | Weihong |

| Position Type | Red dot |

| Power Consumption | ≤21KW |

| Working Voltage | 380V/50Hz |

| Auxiliary Gas | Oxygen,nitrogen,air |

| Working life of fiber module | More than 100000 hours |

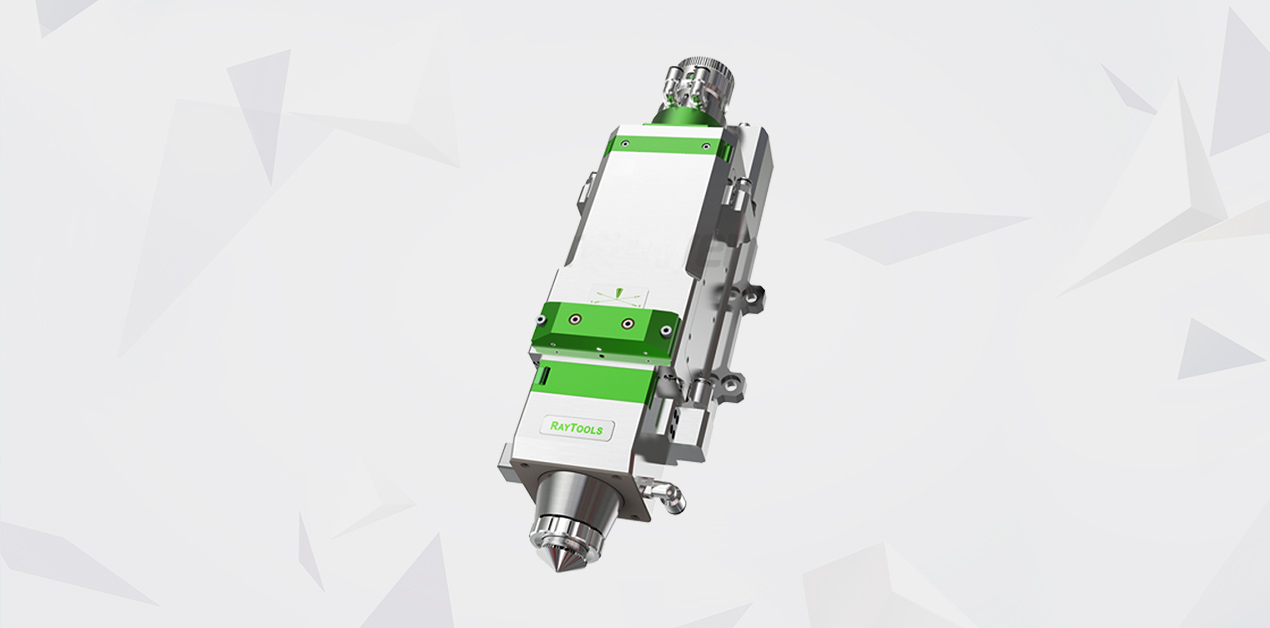

| Cutting Head | Ospri laser head LC40SL |

| Cooling system | S&A/Tongfei/Hanli industrial water chillers |

| Work Environment | 0-45℃,Moisture 45-85% |

| Delivery Time | 15-20 working days(according to the actual season) |

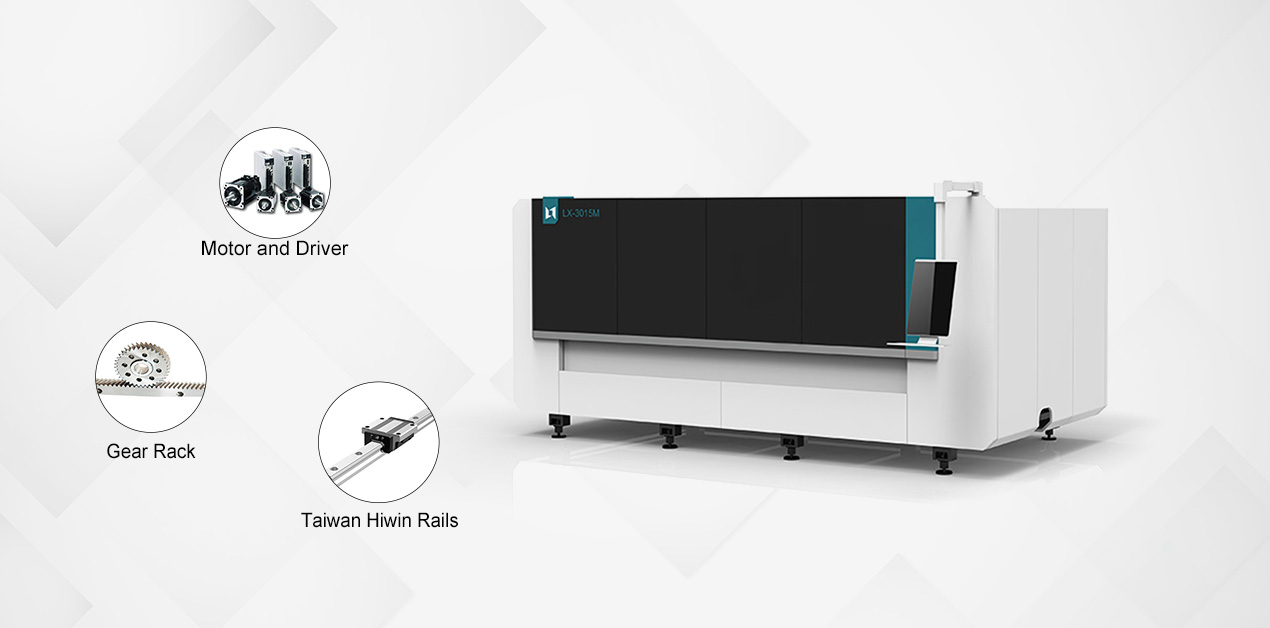

Machine frame

The machine bed of LX3015M desktop laser cutter features high stiffness,temperature resistance and vibration damping.The heavy weight of the bed ensures stability,prevents deformation and suppresses vibration.

Beam

The beam features light weight and a good dynamic performance by adopting an aviation aluminum structure.

Transmission

The Z axis ball screw transmission mode ensures higher efficiency compared with sliding screws.

The Italy WK Te/PEK rails ensure accuracy and high speed thanks to less power loss and smaller heat generated by the operation.

Inovance servo motor features high moving efficiency and vibration suppression.

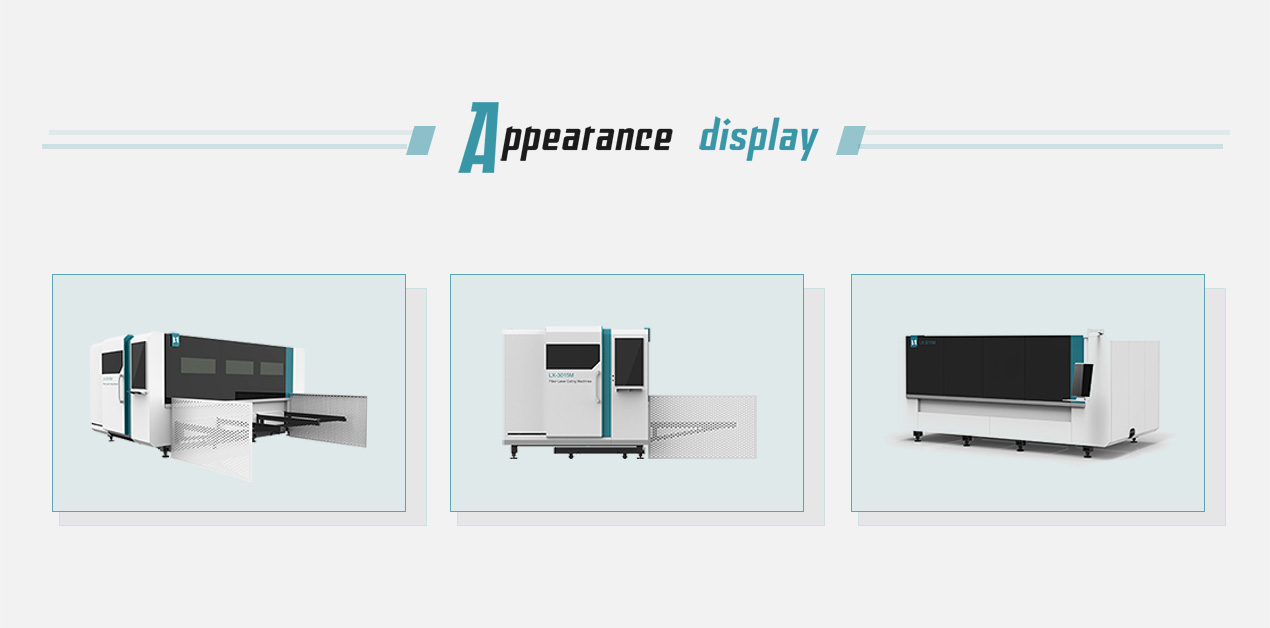

Enclosure

The enclosure design of LX3015M desktop laser cutter helps to protect operators from harmful gases and smokes generated by the operation by filtering them out inside the machine.It can also help to keep the environment clean.

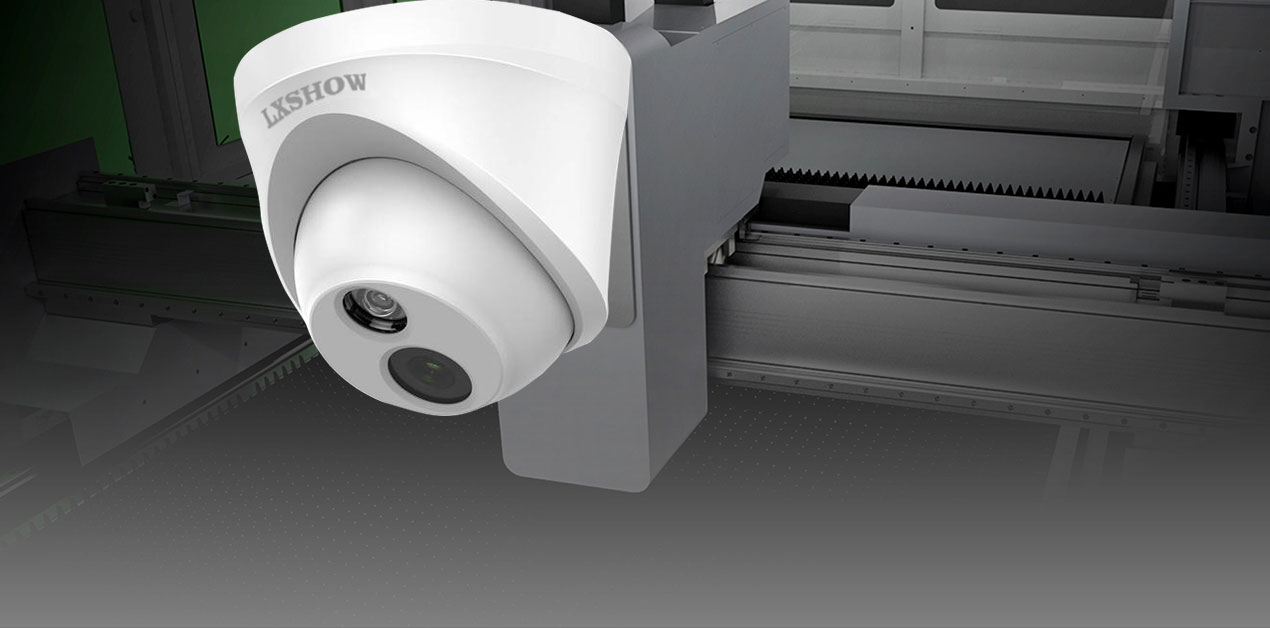

Monitoring system

With the monitoring system, it is much easier to observe the whole production process,so as to prevent potential risks and dangers.

Cutting head

Ospri cutting head comes with auto-focus function to automatically adjust the cutting center.

Independent cabinet

The independent cabinet keeps dust-free and protects the built-in components from dust.

And the built-in air-conditioning also protects them from overheating.

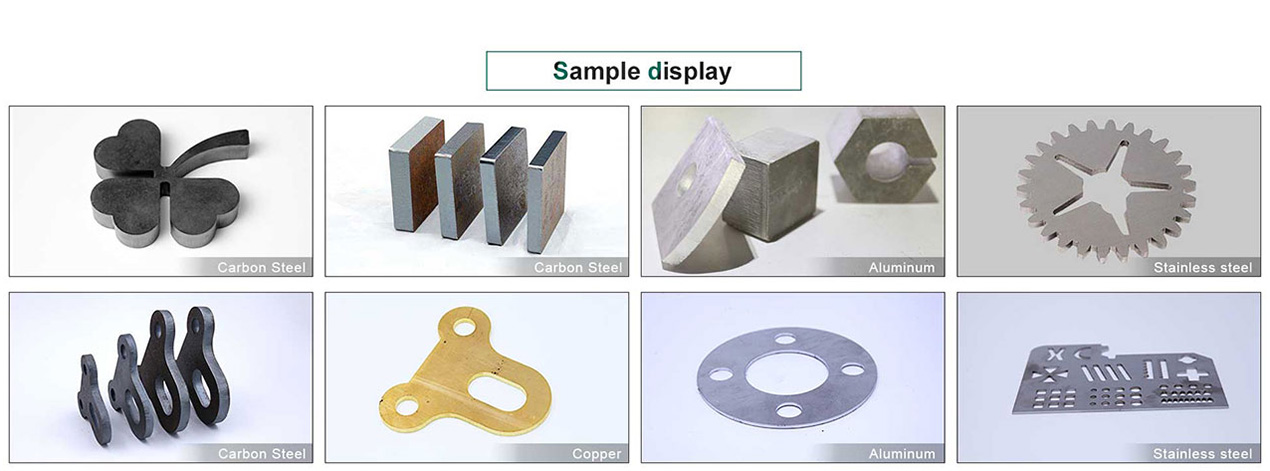

Applicable Materials

Fiber Laser Metal Cutting Machine is suitable for sheet metal like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, etc.

Application Industries

Fiber Laser Cutting Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.