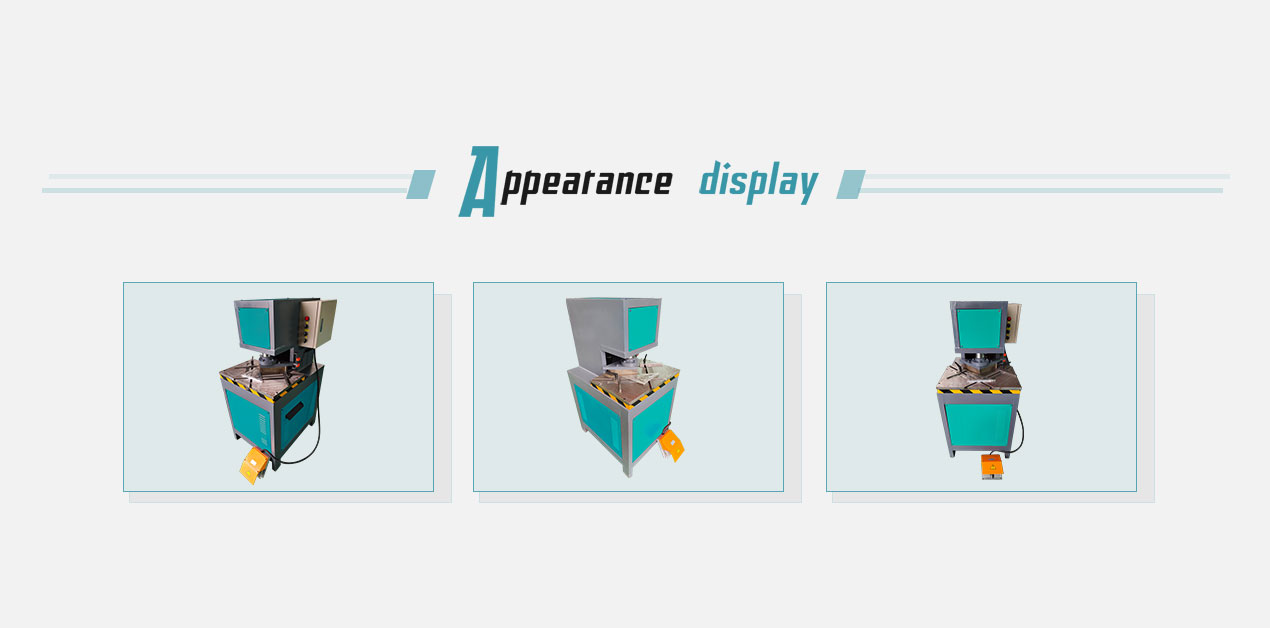

Working principle of Corner Cutting machine

The corner cutting machine is a kind of equipment for cutting metal plates. The corner cutting machine is divided into adjustable type and non-adjustable type. Adjustable angle range: 40°~135°. It can be adjusted arbitrarily within the angle range to achieve the ideal state.

The main structure is welded by the steel plate as a whole, which is strong and durable, and only the tools provided with the standard machine can meet the processing needs of general sheet metal processing plants. It is not necessary to make a set of molds to process workpieces of an angle or a certain thickness like ordinary punching machines, which reduces the cost of use, reduces the trouble of frequent die changing and clamping of ordinary punching machines, improves work efficiency, and reduces labor intensity of workers. Reduce the risk factor of workers, while low-noise processing creates a quiet working environment for factories and workers.

We mainly sell non-adjustable corner cutting machines.

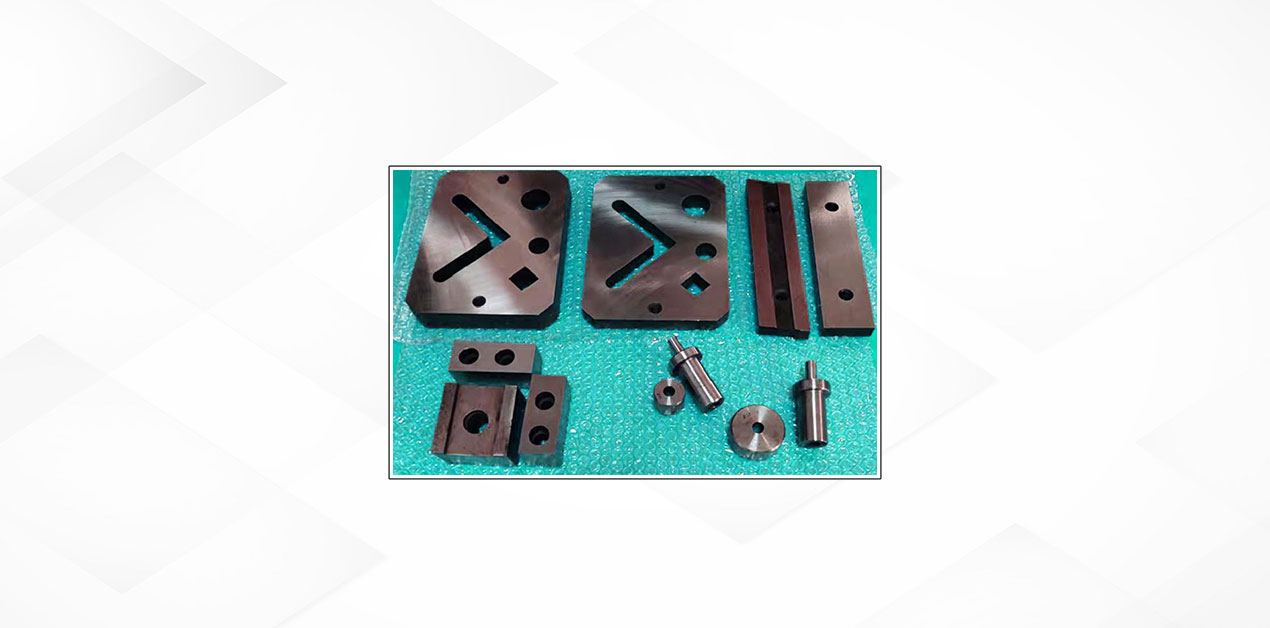

Blade classification

H13: mainly stainless steel

9CrSi: mainly carbon steel, galvanized sheet

Service life: 2 years

The blade is a consumable part. After confirming the material, it is recommended to purchase an additional set of spare blades.

Consumable

Oil cylinder

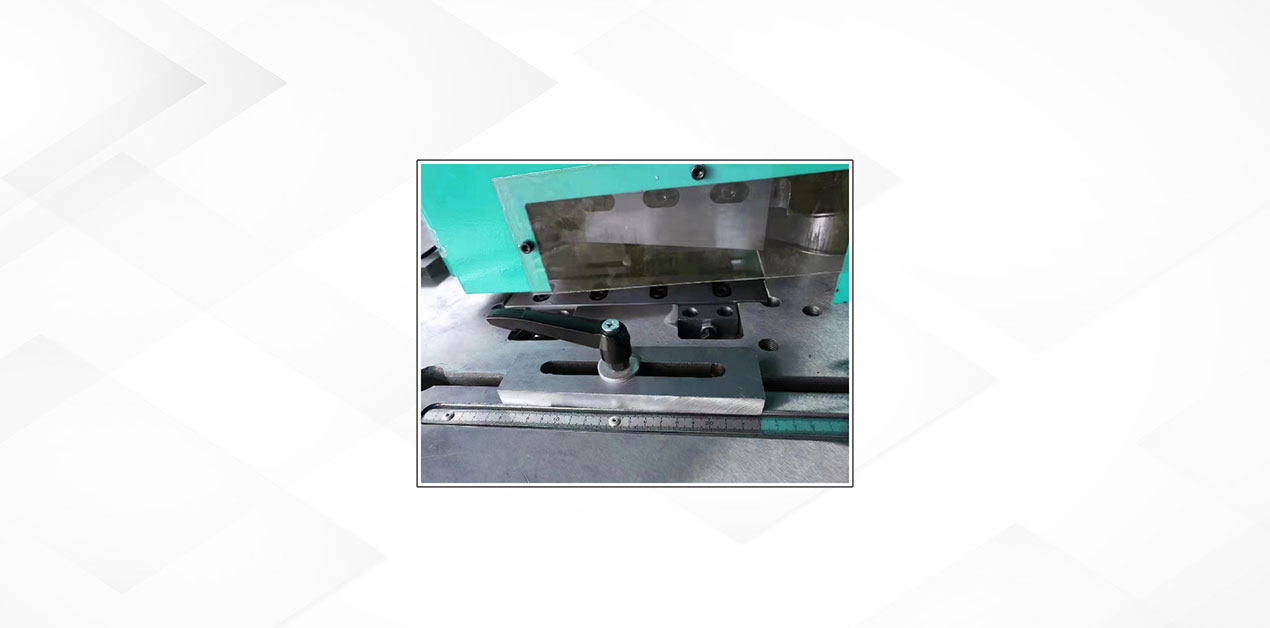

Positioning

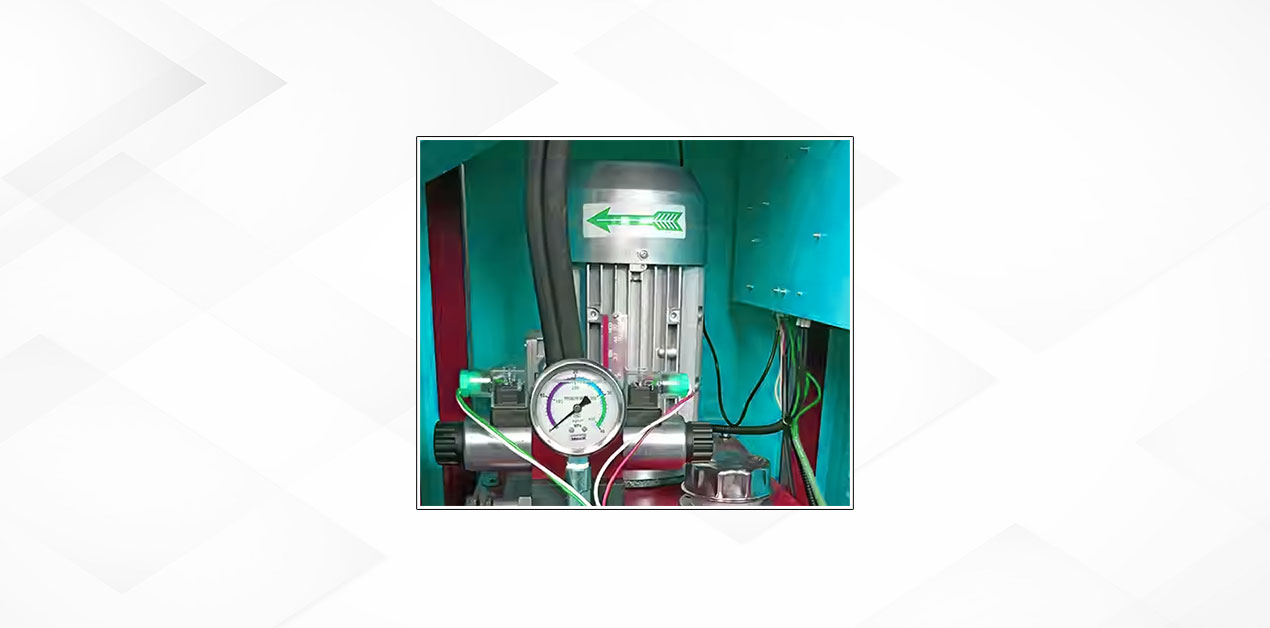

Motor

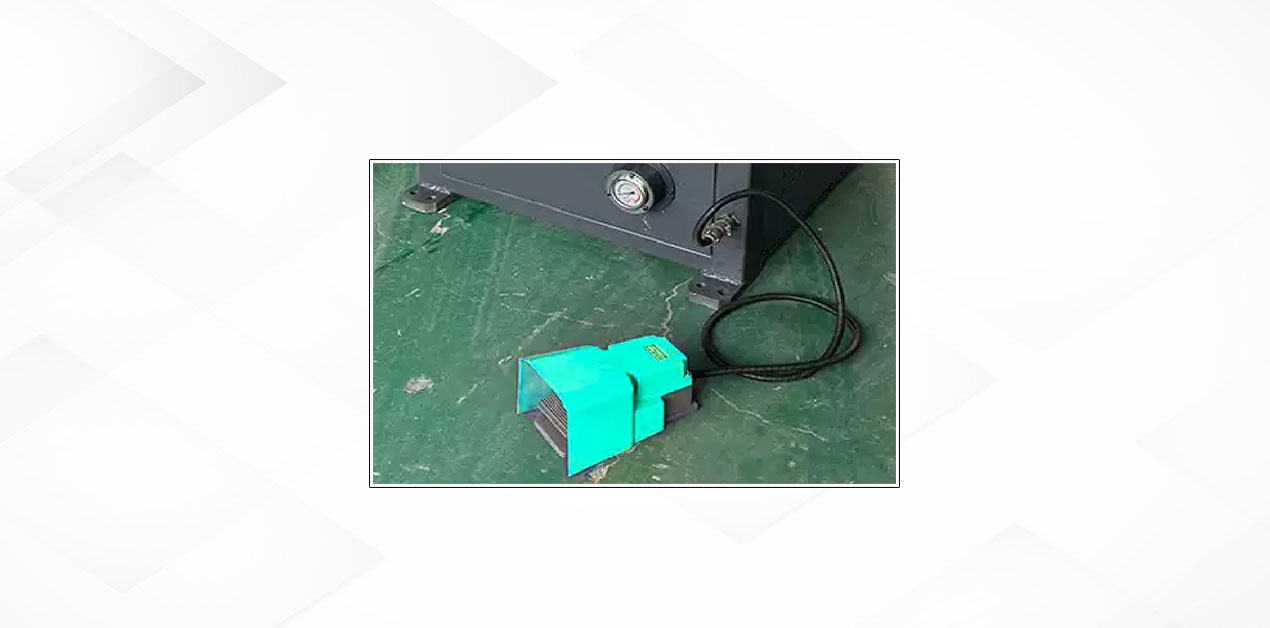

Foot switch

Control panel

Applicable material

Carbon steel, stainless steel, aluminum, copper, high carbon steel and other metals;

Non-metallic plates must be materials without hard marks, welding slag, slag inclusions, and weld seams, and must not be too thick.

Application industry

The corner cutting machine is suitable for cutting metal sheet materials, and it is widely used in many fields such as automobile manufacturing plants, decoration, elevators, electrical equipment, sheet metal electromechanical cabinets, cooking utensils and stainless steel products.