CNC bending machine standard configuration

| Parameters | ||||||

| Model | Weight | Oil Cylinder Diameter | Cylinder Stroke | Wallboard | Slider | Workbench Vertical Plate |

| WG67K-30T1600 | 1.6 tons | 95 | 80 | 18 | 20 | 20 |

| WG67K-40T2200 | 2.1 tons | 110 | 100 | 25 | 30 | 25 |

| WG67K-40T2500 | 2.3 tons | 110 | 100 | 25 | 30 | 25 |

| WG67K-63T2500 | 3.6 tons | 140 | 120 | 30 | 35 | 35 |

| WG67K-63T3200 | 4 tons | 140 | 120 | 30 | 35 | 40 |

| WG67K-80T2500 | 4 tons | 160 | 120 | 35 | 40 | 40 |

| WG67K-80T3200 | 5 tons | 160 | 120 | 35 | 40 | 40 |

| WG67K-80T4000 | 6 tons | 160 | 120 | 35 | 40 | 45 |

| WG67K-100T2500 | 5 tons | 180 | 140 | 40 | 50 | 50 |

| WG67K-100T3200 | 6 tons | 180 | 140 | 40 | 50 | 50 |

| WG67K-100T4000 | 7.8 tons | 180 | 140 | 40 | 50 | 60 |

| WG67K-125T3200 | 7 tons | 190 | 140 | 45 | 50 | 50 |

| WG67K-125T4000 | 8 tons | 190 | 140 | 45 | 50 | 60 |

| WG67K-160T3200 | 8 tons | 210 | 190 | 50 | 60 | 60 |

| WG67K-160T4000 | 9 tons | 210 | 190 | 50 | 60 | 60 |

| WG67K-200T3200 | 11 tons | 240 | 190 | 60 | 70 | 70 |

| WC67E-200T4000 | 13 tons | 240 | 190 | 60 | 70 | 70 |

| WG67K-200T5000 | 15 tons | 240 | 190 | 60 | 70 | 70 |

| WG67K-200T6000 | 17 tons | 240 | 190 | 70 | 80 | 80 |

| WG67K-250T4000 | 14 tons | 280 | 250 | 70 | 70 | 70 |

| WG67K-250T5000 | 16 tons | 280 | 250 | 70 | 70 | 70 |

| WG67K-250T6000 | 19 tons | 280 | 250 | 70 | 70 | 80 |

| WG67K-300T4000 | 15 tons | 300 | 250 | 70 | 80 | 90 |

| WG67K-300T5000 | 17.5 tons | 300 | 250 | 80 | 90 | 90 |

| WG67K-300T6000 | 25 tons | 300 | 250 | 80 | 90 | 90 |

| WG67K-400T4000 | 21 tons | 350 | 250 | 80 | 90 | 90 |

| WG67K-400T6000 | 31 tons | 350 | 250 | 90 | 100 | 100 |

| WG67K-500T4000 | 26 tons | 380 | 300 | 100 | 110 | 110 |

| WG67K-500T6000 | 40 tons | 380 | 300 | 100 | 120 | 120 |

Bending machine product accessories

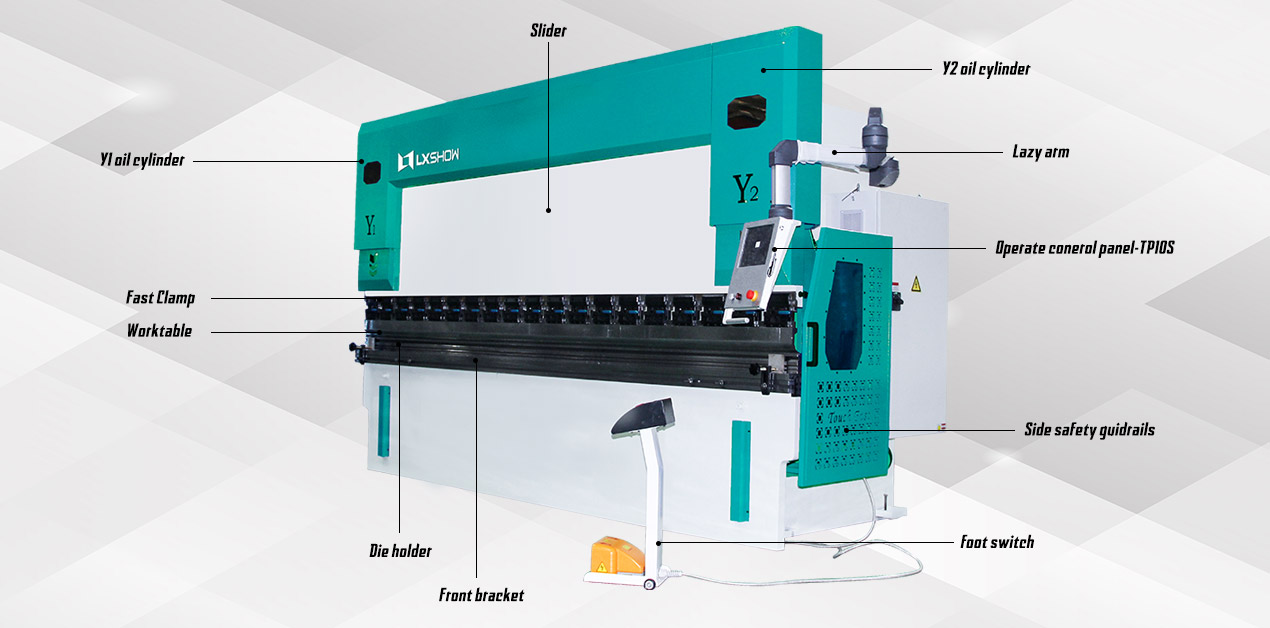

CNC bending machine standard configuration

Features

Complete steel-welded structure, with sufficient strength and rigidity;

Hydraulic down-stroke structure, reliable and smooth;

Mechanical stop unit, synchronous torque, and high precision;

The backgauge adopts the backgauge mechanism of the T-type screw with smooth rod, which is driven by a motor;

Upper tool with tension compensating mechanism, In order to guarantee high precision of bending;

TP10S NC system

CNC system

TP10s Touch screen

Support angle programming and depth programming switchin

Support settings of mold and product library

Each step can set opening height freely

The shift point position can be freely controlled

it can realize Multi-axis expansion of Y1、 Y2、 R

Support mechanical crowning workingtable control

support large circular arc automatic generate program

Support top dead center, bottom dead center, loose foot, delay and other step change options, it improve processing efficiency effectively

Support electromagnet simple bridge

Support fully automatic pneumatic pallet bridge function

Support automatic bending, realize unmanned bending control, and support up to 25 steps of automatic bending

Support time control of valve group configuration function, fast down, slow down, return, unloading action and valve action

it has 40 product libraries, each product library has 25 steps, large circular arc supports 99 steps

Upper Tool Fast Clamp

Upper tool clamping device is fast clamp

Multi-V Bottom Die Clamping(option)

Multi-V bottom die with different openings.

Backgauge

Ball screw/liner guide are high precision.

Front Support

Aluminium alloy material platform ,attractive appearance,and decrease scratch of workpicec.

Bending machine opintional parts

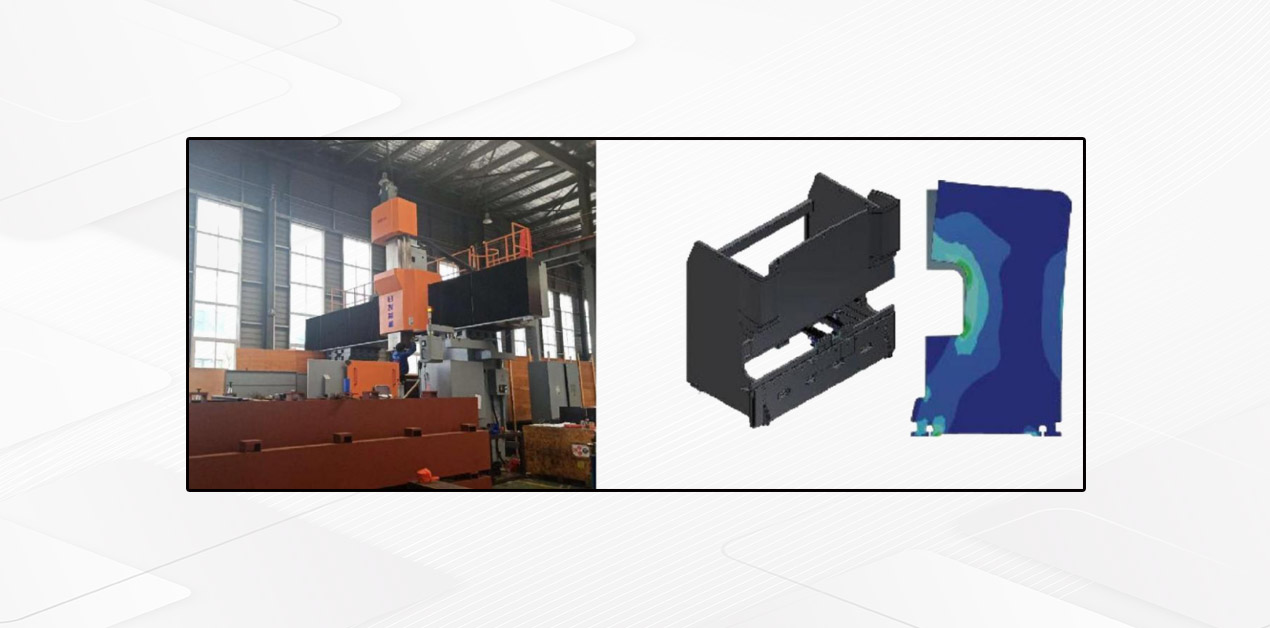

Crowning Compensation for Worktable

A convex wedge consists of a set of convex oblique wedges with a beveled surface. Each protruding wedge is designed by finite element analysis according to the deflection curve of the slide and worktable.

The CNC controller system calculates the required compensation amount based on the load force. This force causes deflection and deformation of the vertical plates of the slide and table. And automatically control the relative movement of the convex wedge, so as to effectively compensate for the deflection deformation caused by the slider and the table riser, and obtain the ideal bending workpiece.

Quick Change Bottomm Die

Adopt 2-v quick change clamping for bottom die

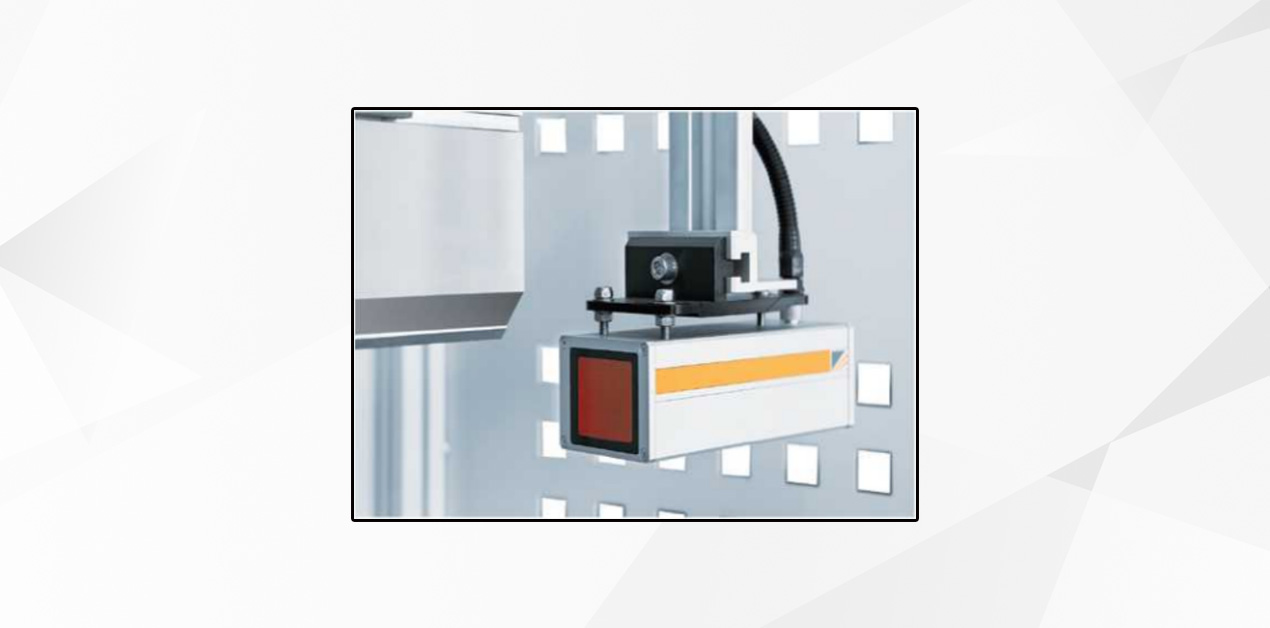

Lasersafe Safety Guard

Lasersafe PSC-OHS safety guard, communication between CNC controller and safety control module.

Dual beam from protection are point below 4mm below the tip of upper tool,to protect operator's fingers;three regions(front,middle and real) of leaser can be flexibly closed,ensure complex box bending processing ;mute point is 6mm,to realize efficient and safe production.

Mechanical Servo Bending Help

When mark bending support plate can realize the function of turning over following.following angle and speed are calculated and controlled by CNC controller,move along linear guide left and right.

Adjust the height up and down by hand, front and rear can also be adjust manually to suit for different bottom die openning

Support platform can be brush or stainless steel tube ,according to workpiece size,two supports linkage movement or seperate movement can be chosed.

Performance features

Slider adopts torsion shaft synchronous mechanism ,also install high-precision taper centering bearings (“K”model) at both ends of torsion shaft and install eccentric adjustment mechanism at the left end in order to make slider synchronous adjustment convenient and reliable.

Adopts Upper tool with tension compensating mechanism,upper tool port obtains a specific curves over the full length of the machine and deflection of worktable and slider improve bending accuracy of the tools when crowning through adjustment

During the angle adjustment,the servo worm drives the movement of the mechanical stop in the cylinder,and the cylinder position value is displayed by the stroke counter.

The fixed place of the worktable and wallboard is equipped with an upper and lower adjustment mechanism ,which makes the adjustment convenient and reliable when the bending angle is slightly different.

The right side of the column is equipped with a remote pressure regulator, which makes the system pressure adjustment, convenient and reliable.

Hydraulic system

Adopts advanced integrated hydraulic system reduces the installation of pipelines and ensures a high degree of reliability and safety in the operation of the machine.

The speed of the slider movement can be realized. Rapid descent, slow bending, fast return back action, and fast down, slow down speed can be adjusted appropriately.

Electric control system

Eletrical component and material meet international standards,safe,reliable and long life.

The machine adopts 50HZ, 380V three-phase four-wire power supply.The motor of machine adopts three-phase 380V and the line lamp adopts single phase-220V.The control transformer adopts two-phase 380V.The output of the control transformer is used by the control loop, among which 24V is used for back gauge control and for electromagnetic reversing valves. 6V supply indicator, 24V supply other control components.

The electrical box of the machine is located on the right side of the machine and is equipped with a door opening and power-off device.The operate component of machine are all concentrated on the electrical box except the foot switch, and the function of each operating stacked element is marked by the image symbol above it.It can automatically cut off the power supply when opening the electric box door, and if it needs to be repaired live, it can be manually reset to pull out the micro switch lever.

Front and back gauge

Front bracket: It is Placed on the side of the worktable and secured by screws. It can be used as a support when bending wide and long sheets.

Back gauge: It adopts back gauge mechanism with ball screw and linear guide is driven by servo motor and a synchronous wheel timing belt. The high-precision positioning stop finger can be easily moved left and right on the double linear guide rail beam, and the workpiece is bent "as you like".