When marking processing, the processing parts must be in a fixed position, and the patterns of the machining process can not shake, can be processed to products on the specified location, these are our common sense of ordinary laser marking machining technology.Now new technology constantly emerging, our newly developed visual location of laser marking machine, which can realize products as long as the laser marking processing range scanning galvanometer, can achieve precise marking.Where each position even if they don't like.Processing position is also OK.CCD visual laser marking machine to use visual positioning principle.First to template for products.Saved as a standard template.Photograph products during processing.Contrast and position location by computer.Can be adjusted for precise processing of product.Products manufactured by shape can be round, square, irregular shape can be identified.This process is especially suitable for small products.Can be exempted from positioning tray, fixed jig processing.Greatly save the laser marking processing cycle.

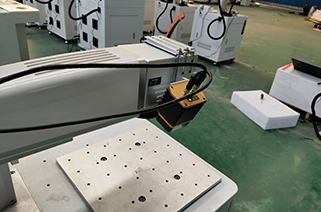

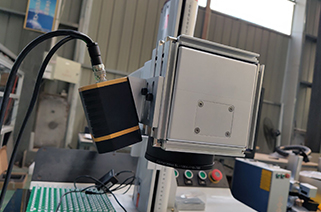

The pictures of Visual Positioning:

The following is video link:

https://www.youtube.com/watch?v=cKyd3PHP26c

The next is samples:

This Visual positioning can be equipped on desktop fiber laser marking machine also can be equipped on portable fiber laser marking machine.But the field lens will be 110mm.

There are many advantages of Visual positioning equipment :

1, camera imaging field of vision.Apply to any planar product marking;

2, product arbitrary Angle, automatic identification of an arbitrary number, camera product marking,

3, with optical fiber, CO2, such as the wavelength of semiconductor laser light path integration,

4, through the guide rail control can realize the joining together of large-format product marking,

5, take up the space is little, do not take up any space of the working platform, the existing laser installation space can be upgraded,

6, can increase the XYZ axis according to the actual product features.Realize fully automated visual position marking.

And Visual Positioning will be applied to:

Widely used in USB shell, U disk, following, jewelry, watches, back cover, car keys, a ticket, drill bits, buttons, and other fields of high precision, automatic marking, suitable for big workload, for had a difficult, workpiece diversified complexity, etc.