Plexiglass is a thermoplastic, the scientific name polymethyl methacrylate, which is called plexiglass because it has the same transparency as glass. It has good light transmission, flame resistance, heat resistance, cold resistance, corrosion resistance, weather resistance, electrical insulation, etc. The main characteristics are light weight, high strength, easy processing and easy coloring. Automobiles, ships, lighting, electronics, optical instruments, instruments, medical equipment, building materials, stationery and other fields are widely used.

The strength of plexiglass itself is relatively high, and the tensile and impact resistance is 7 to 18 times that of ordinary glass. After professional heat treatment and stretching treatment, the toughness of the material can be significantly improved. It has a crystal-clear and translucent luster after polishing, and is therefore widely used in the manufacture of medical containers, transparent covers for medical equipment, sight glasses and surgical instruments.

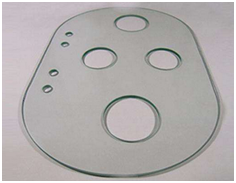

Plexiglass is easy to process, not only can be cut and drilled on the vibrating knife cutting machine, but also can be bonded into various shapes of vessels with organic solvents such as acetone and chloroform. It can also be used for blow molding and injection. Plastic molding methods such as extrusion are made into various medical products, ranging from medical equipment covers to dental products such as dentures and dental trays. Studies have shown that plexiglass can be compatible with human tissues, harmless to human body, good light transmission, stable chemical properties, easy to process into the desired shape, so it is also used to make artificial cornea.

Previous:

LXSHOW wait for you in Canton Fair

Previous:

LXSHOW wait for you in Canton Fair