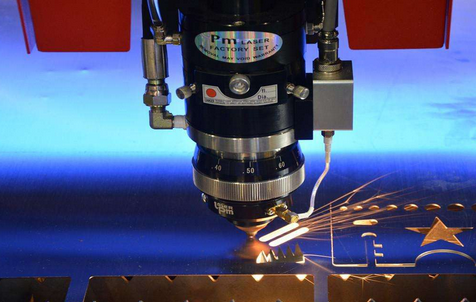

The fiber laser cutting machine has the characteristics of high precision, fast cutting speed, material saving, stable cutting and low processing cost. However, in the process of cutting, there are differences in operating procedures, and irregular metal parts such as burrs may appear at the transition surface of the workpiece. . Although the deburring process was adopted in the production process of the product, the burr problem was not strictly solved, and the burr quietly affected the product quality, leaving the product with subsequent inspection, assembly, performance and aesthetics. Let us analyze the causes and solutions of the burrs.

1. Because of the deviation of the upper and lower positions of the focus of the laser beam

Solution: Adjust the position of the focus and adjust it according to the offset position it produces.

2. The output power of the laser cutting machine is not enough

Solution: Check if the laser cutting machine is working properly. If it is not normal, it needs timely repair and maintenance. If it is normal, check if the output value is correct.

3. The laser cutting machine wire cutting speed is too slow

Solution: Adjust and increase the speed of wire cutting in time.

4. The purity of the auxiliary gas of the laser cutting machine is not enough.

Solution: Explain the increase in the purity of the auxiliary gas.

5. The laser beam of the laser cutting machine is offset.

Solution: Perform focus debugging and make adjustments in time.

6. Unstable due to the long operating time of the laser cutting machine

Solution: Turn off the machine and let the machine rest.