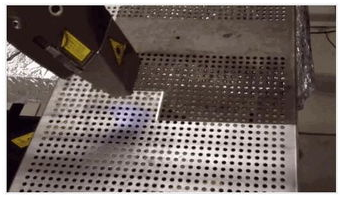

1. Light dry cleaning method, that is, direct radiation radiation decontamination using pulsed laser.

2. Laser + liquid film method, that is, first deposit a liquid film on the surface of the substrate, and then decontaminate with laser radiation.

3. Laser + inert gas method, that is, while the laser radiation, the inert gas is blown to the surface of the substrate, and when the dirt is peeled off from the surface, it will be immediately blown off the surface by the gas to avoid re-contamination and oxidation of the surface.

4. After using the laser to loosen the dirt, clean it with non-corrosive chemical methods.

The most common are the first three methods. The fourth method is only found in the cleaning of stone artifacts.

Internationally, laser cleaning technology has been applied to stone materials for more than a decade. Since the investment in laser equipment is still relatively expensive, it is still difficult to generalize the application. However, laser cleaning technology has the advantages that traditional cleaning methods can't match. With the continuous improvement of technology and mass production of equipment, laser cleaning technology will play an important role in the cleaning of stone materials.