Although fiber laser cutting machines are widely used in the machining industry, many friends are no strangers to it, but for their components are well-informed, let us understand what the composition of the fiber laser cutting machine is.

The fiber laser cutting machine is mainly composed of a power control cabinet, an electric operation console, a water cooler, a fiber laser generator, and a bed.

The working system includes electrical control system, drive system, transmission system, optical system, circulating cooling system, pneumatic system, discharge system, dust removal system and lubrication system.

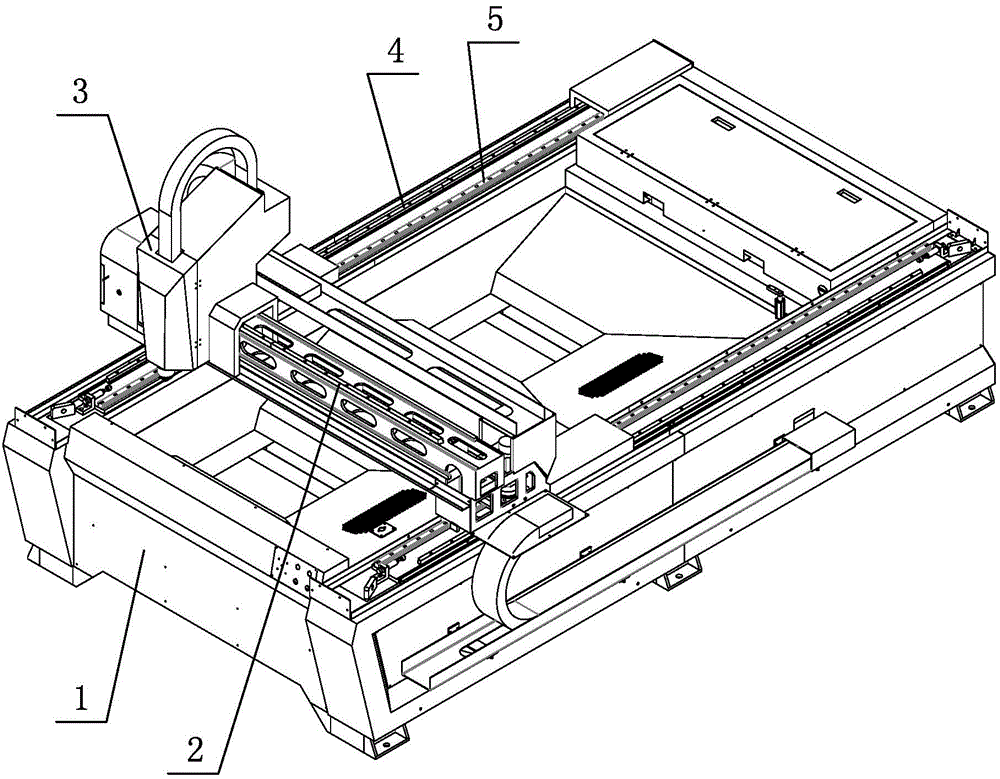

1. Main part of the machine tool: The mechanical part of the laser cutting machine, which realizes the movement of the X, Y and Z axes, including the cutting work platform.

2. Laser generator: The laser beam energy is used to cut the power of the material. It is the core component of the laser cutting machine and the price is relatively expensive.

3. Servo motor: It can control the cutting speed. The position accuracy is very accurate. The voltage signal can be converted into torque and speed to drive the control object. The rotor speed of the servo motor is controlled by the input signal.

4. External light path: A refractive mirror that directs the laser to the desired direction. In order to prevent the beam path from malfunctioning, all mirrors are protected by a protective cover and a clean positive pressure shielding gas is introduced to protect the lens from contamination.

5. CNC system: Control the machine tool to realize the movement of the X, Y and Z axes, and also control the output power of the laser.

6. Regulated power supply: connected between the laser, CNC machine and power supply system. Mainly to prevent the interference of the external power grid.

7. Cutting head: mainly includes parts such as cavity, focusing lens holder, focusing mirror, capacitive sensor and auxiliary gas nozzle. The laser beam is irradiated onto the surface of the material through the cutting head for processing operations.

8. Operator station: used to control the working process of the entire cutting device.

9. Chiller: used to cool the laser generator. A laser is a device that converts electrical energy into light energy. For example, a CO2 gas laser typically has a conversion rate of 20%, and the remaining energy is converted into heat. The cooling water carries excess heat away to keep the laser generator working properly. The chiller also cools the external light path mirror and focusing mirror of the machine tool to ensure stable beam transmission quality and effectively prevent the lens from overheating and causing deformation or bursting.

10. Cylinders: including laser cutting machine working medium cylinders and auxiliary cylinders, used to supplement laser-oscillated industrial gases and auxiliary gases for cutting heads.

11. Air compressor, air tank: Provide and store compressed air.

12. Air Cooling Dryer, Filter: Used to supply clean dry air to the laser generator and beam path to maintain proper operation of the path and mirror.

13. Exhaust dust remover: Extract the dust and dust generated during processing, and carry out filtration treatment to make the exhaust emission comply with environmental protection standards.

14. Slag discharge machine: Excluding the residual materials and scraps generated during processing.