Different laser cutting machines have different cutting priorities. The price of fiber laser cutting machine on the market is much higher than that of YAG laser cutting machine. So, what are the differences between the two laser cutting machines as the mainstream of the market?

1. From the perspective of processing

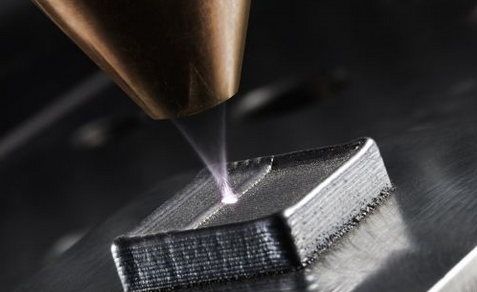

YAG laser cutting machine has low cost of purchase and can cut high-reflective materials, such as non-ferrous materials that cannot be cut by fiber laser cutting machines such as aluminum and copper. However, the YAG laser cutting machine can cut only a small-power laser cutting material of less than 8 mm, and the cutting efficiency is much slower than that of the optical fiber laser cutting machine, and the efficiency is relatively low. Fiber laser technology enables very high power in very small packages, so it occupies less space and saves space.

2. From the perspective of cost

The YAG laser is a laser that has been developed for decades and has mature technology. Therefore, the price of the YAG laser cutting machine is relatively cheap. But with the popularity of fiber lasers, this advantage is getting weaker. In addition, the power consumption of the YAG laser cutting machine is large during processing.

3. From a maintenance perspective

Since there is no optical lens in the cavity of the fiber laser, it has the advantages of no adjustment, no maintenance, and high stability, so the maintenance and replacement of the device is relatively simple. This is unmatched by traditional YAG lasers.