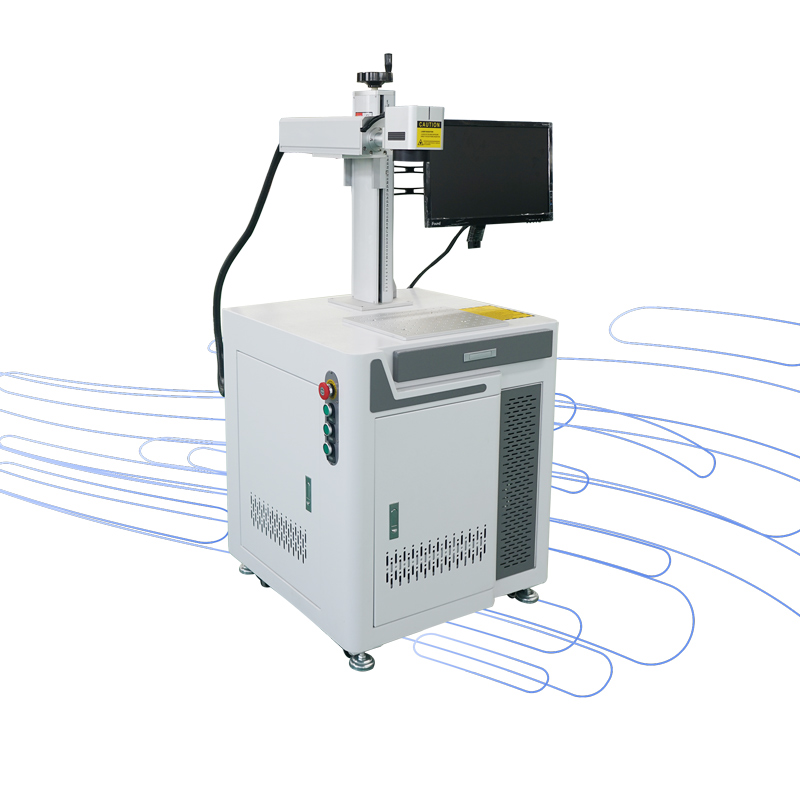

Ultraviolet laser marking machine can be used for ultra-fine marking and special material marking because it has very small focusing spot and small processing heat affected zone. It is the preferred product for customers who have higher requirements for marking. The UV laser marking machine has the advantages of fast marking speed and high efficiency; stable performance, small size and low power consumption.

Ultraviolet laser marking machines generally have 5w, 10w, 15w, 20w. These markets use more power. The higher the power, the higher the price. The higher the power, the wider the application range.

Personally, it is recommended to use 5W equipment as far as the economy allows, and the equipment is more scalable and has more room for preservation. Mainly marking some flexible PCB board marking, silicon wafers, plastic buttons, electronic components, gifts, high-demand transparent buttons, UV plastic parts and other materials that are particularly sensitive to light.

The 10-20W equipment is expensive, mainly used in high-end precision cutting and precision punching. Mainly used in high-end precision cutting and precision punching. There are mainly materials such as FPC, ceramic sheets, glass sheets and other processes that are difficult to cut.