In the aluminum smelting industry, primary aluminum production is usually the use of carbon blocks as "sacrificial" anodes. The environmental, economic and technical aspects of aluminum production have a large impact on the quality of the anode.

A small portion of the battery power is used to overcome the resistance of the prebaked anode. The presence of dirt and other contaminants increases the resistance of the anode, resulting in more battery power. The presence of contaminants also shortens their life by increasing the rate of consumption of the anode during the smelting process. From an efficiency standpoint, it is necessary to clean and remove all contaminants on the surface of the anode assembly before being used in aluminum smelting operations.

In addition, the anode assembly is a valuable tool that can be reused, but its main components must be thoroughly and carefully handled under specific conditions.

Laser cleaning can meet specific conditions for reusable anode components. Laser cleaning can be used to:

◎ Remove carbon residue

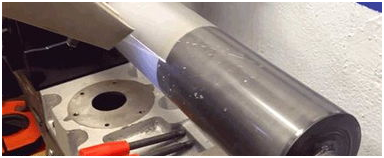

◎ Clean cathode rod

◎ Remove contaminants from casing and short rods