Laser cleaning industry has a variety of the traditional way, most use of chemical and mechanical methods for cleaning.In our country, more and more strict environmental protection laws and regulations, growing awareness about environmental protection and safety, industrial cleaning chemicals can be used in species will become less and less.How to find more clean, and not of the nature of injury cleaning method is a problem we have to consider.And laser cleaning has no grinding, non-contact, no thermal effect and is suitable for all kinds of objects such as cleaning, is considered the most reliable and effective solutions.At the same time, laser cleaning can be solved by traditional cleaning method can not solve the problem.

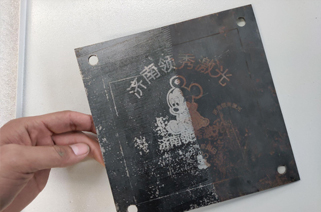

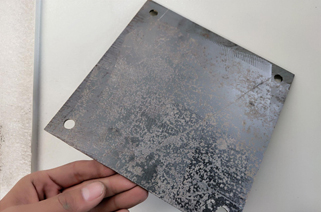

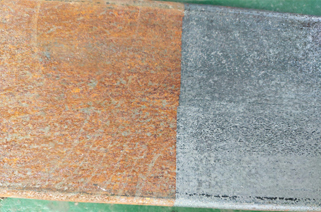

Samples of laser cleaning machine show:

Work video Link:

https://www.youtube.com/watch?v=h_o0sZ23_p0

https://www.youtube.com/watch?v=Hnoq1yDqecE

Comparing with traditional cleaning way,laser cleaning has following advantages:

1 laser cleaning is a kind of "protective" cleaning method, without using any chemicals and cleaning fluid, cleaning down waste, basically all is solid powder, small volume, easy to store, recyclable, can easily solve the problem of environmental pollution caused by chemical cleaning.

2 traditional cleaning methods are often contact cleaning, has mechanical force to the cleaning surfaces, damage the surface of the object or cleaning medium adhesion on the surface of the object to be clean, not remove, produce secondary pollution, laser cleaning of grinding and non-contact these problems solved;

3 laser can through the optical fiber transmission, to match the machine hand and robots, convenient to realize remote operation, can clean the traditional method is not easy to achieve, it used in some dangerous places can ensure the safety of the staff;

4 laser cleaning can remove all kinds of materials on the surface of the various types of pollutants, achieve the cleanliness of regular cleaning cannot achieve.And still can not damage the material surface under the condition of selectively cleaning contaminants on the surface of the material;

5 laser cleaning efficiency, save time;

6 to buy laser cleaning system although preliminary one-time investment is higher, but the cleaning system can be used long-term, stable, low running cost, LASERLASTE “Quantel”company, for example, the operating cost per hour is only about 1 euro, more important is can easily realize automation.