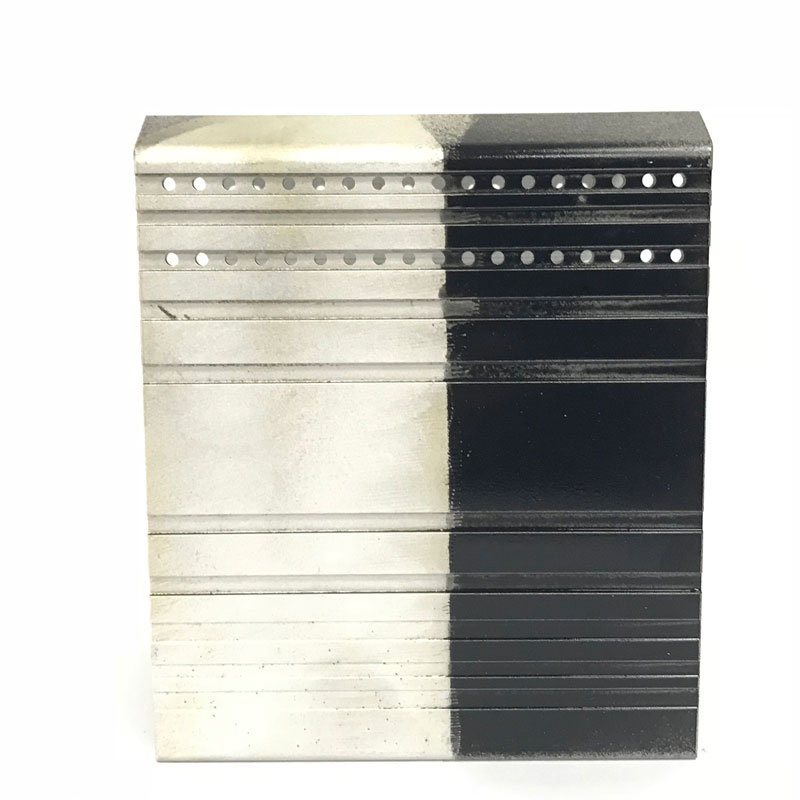

Laser cladding is a new surface modification technology. It adds a cladding material on the surface of the substrate and uses a high-energy density laser beam to fuse it with a thin layer on the surface of the material to form an additive cladding layer combined with metallurgy on the surface.

Laser cladding refers to placing the selected coating material on the surface of the cladding material by different addition methods. After laser treatment, it is melted at the same time as the thin layer of the material surface, and quickly solidifies to form a very low degree of substitution. The alloyed surface coating significantly improves the wear resistance, corrosion resistance, heat resistance, oxidation resistance and electrical characteristics of the base surface, so as to achieve the purpose of surface modification or repair, which satisfies the material The specific performance requirements of the surface are also valuable elements for cost saving.

With surfacing, spraying, electroplating and vapor deposition deposition, laser cladding has the characteristics of small substitution, dense structure, good combination of coating and substrate, suitable for many cladding materials, large changes in particle size and content, etc. Therefore, laser cladding technology is applied The prospect is very broad