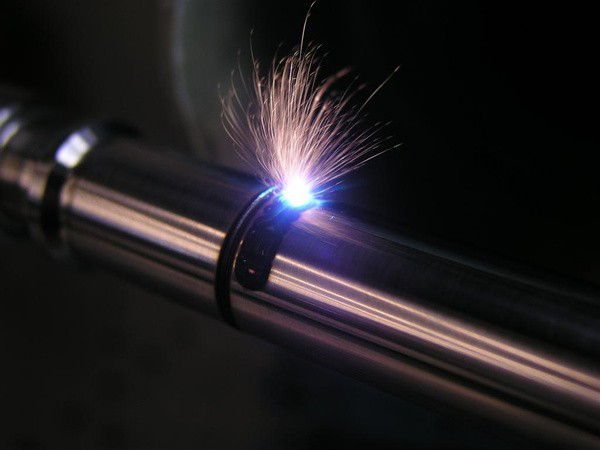

When marking laser marking machine, we often see sparks in some places. In many cases, this phenomenon will lead to poor marking of the product. This phenomenon indicates that the marking of the product has been too large on the surface of the product. , the product has caused excessive power marking. Let's take a look at how to deal with this situation.

Avoid the phenomenon of sparking. Pay attention to the following points:

1. Increase the laser frequency of the laser marking machine.

2. Optimize the spot pattern of the laser.

3. Change the distance between the marking airport mirror and the workpiece, that is, do a certain defocus.

4. Add auxiliary gas during the processing. For example, in the processing of wood blocks by CO2 laser marking machine, cheap nitrogen can be added, which can make the wood blocks after marking have no black effect.

5. the use of femtosecond laser, that is, high-frequency laser can achieve the effect of approximate cold processing.

6. The use of ultra-short-wavelength lasers, such as UV laser marking machines, can also achieve the effect of near-cold processing. The energy of the laser directly destroys the atoms of the processed material.