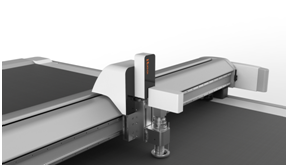

For the vibrating knife cutting system, the vibrating knife mechanism, the vibrating knife falling block, and the vibrating knife falling bar are the main components on the base. The vibrating knife mechanism comprises a vibration motor, a vibration knife and a transmission bushing, a transmission connecting rod, a transmission shaft and an eccentric wheel; the transmission bushing is fixed on the vibration knife falling block, and the driving shaft sleeve is further provided with a rotary knife motor. The first transmission pulley; the vibration cutter falling block is fixed on the vibration knife falling knife air rod. The vibrating knife cutting system has a simple structure, strong applicability, high control precision and easy maintenance.

Vibration cutting allows more companies to bid farewell to the traditional manual knife cutting process, without the need to create a die, thus saving the cost of production and management of the die-making management, which means entering a new era of digital toolless machining.

When you have a desire to buy a vibrating cutter, it is necessary to understand the configuration of the vibrating cutter. This is the most important, because only by understanding these can you understand the performance of the vibrating cutter. Here are the following:

Can cut honeycomb paperboard, acrylic sheet, corrugated paper, plastic corrugated board, gray board paper, white cardboard, film, composite materials, leather, cloth, rubber sheet, pearl cotton, aluminum composite board and foam KT board, etc. More than 50mm flexible non-metallic materials, the head of the vibration cutting machine is equipped with a vibrating knife, pen, pressure roller, dragging knife, etc. The supporting products of the vibration cutting machine are vacuum pump and machine control software.