As we all know, in the computer embroidery and cloth toy industry, all kinds of primers need to be cut by the die, the application of laser cutting technology, various problems when the die cuts the fabric (the effect is not ideal, the cloth is stripped) is solved. Laser cutting machines have advantages for fabrics with a high polyester or polyamide content. Because the laser can slightly melt the edges of such fabrics to form a welded edge that does not scatter, no additional processing is required. The laser cutting machine can achieve a cutting speed of 40 m/min with “light” generation, and it runs smoothly and has a clean cut. It can effectively solve the problems of computer embroidery, garment proofing and other industries in the process of using mechanical cutting. Many difficult issues.

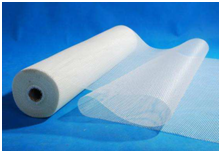

In the past, glass fiber cloth was cut by hand, the efficiency was low, the cutting precision was poor, and some special shapes also needed manual completion, and the manufacturing process was complicated. The vibrating knife cutting machine adopts fully automatic intelligent cutting system. It can cut at one time in straight line or special shape without manual measurement cutting. In addition, most cutting equipment will produce a lot of powder splash when cutting. Our machine tool adopts vacuum adsorption. The system firmly adheres the powder to the equipment itself. In the special cutting, the cutting machine can be equipped with a visual identification system, automatically identify materials, automatically typeset, and greatly reduce the labor cost and improve efficiency.

Laser processing equipment used in the apparel industry, high-speed laser cutting machine, automatic laser cutting machine, laser cutting machine, mutual shift double-head laser cutting machine, automatic laser cutting machine and laser marking machine. A laser cutting machine is a cutting machine that cuts a fabric with a laser. It consists of a cutting bed, a metal lining, a laser cutting head, a transverse guide for the drive positioning device, a longitudinal rail and a laser.

We have a variety of professional supporting equipment, advanced production technology, a sound quality assurance system, strict quality control, excellence, high product qualification rate. Under the continuous efforts of scientific and technical personnel, we have gathered the strengths of the public and carefully developed mechanical products. The technical indicators have prioritized the national standards and are among the best in the industry.