Fiber laser cutting machines are gradually replacing the traditional processing methods and become one of the main tools for metal processing in modern enterprises. Because the laser cutting machine is a new type of processing equipment, it has not been accepted by the industry for several reasons:

1. For some industries, the existing machines can meet the production needs, so I have not gone deep into the metal laser cutting machine, so I am not familiar with it.

2. Compared to traditional machines, the price factor is also one of them. The price of metal laser cutting machines is much more expensive than traditional machines.

3. The main point is, is the metal laser cutting machine easy to use and how much work efficiency can it increase? This is a question that everyone is more concerned about.

Then let's take a look at the working principle of metal laser cutting machine to see why laser cutting machine works well and why it can greatly increase work efficiency.

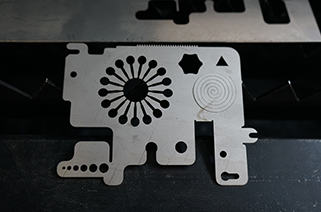

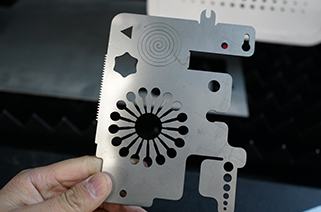

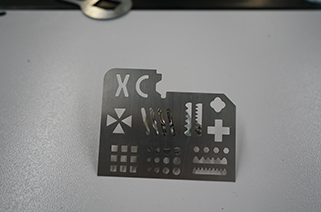

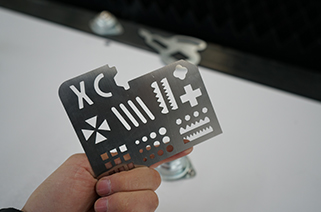

The key of metal laser cutting machine is laser processing technology. Laser cutting is to use a focused high power density laser beam to irradiate the workpiece, so that the irradiated material melts, vaporizes, ablates or reaches the ignition point, and at the same time uses the high-speed airflow coaxial with the beam The molten material is blown away to achieve workpiece cutting.

Stainless steel is widely used in the decoration engineering industry due to its characteristics of corrosion resistance, high mechanical properties, stable surface color, and color changes with different light angles. For example, in the decoration and decoration of local buildings such as entertainment clubs and public places of public leisure, it is used as materials for making decorative objects such as curtain walls, hall walls, elevator decorations, signboard advertisements, and front screens.

However, making stainless steel plates into stainless steel products is a very complicated task. Many manufacturing processes are required during the manufacturing process, such as cutting, folding, bending, and welding. Among them, the cutting process is a relatively important process. There are many traditional processing methods for stainless steel cutting, but the efficiency is low, the molding quality is poor, and it is rarely able to achieve the needs of mass production.

At present, stainless steel laser cutting machines are used in metal processing and decorative engineering industries due to their characteristics of good beam, high precision, small slits, smooth cut surfaces, and the ability to cut arbitrary graphics. With the increasingly fierce market competition, laser cutting will play an increasingly important role and bring economic benefits.

Next is video of Fiber laser cutting machine: